Selection of Ceramic Fibers in Different Stages for Carbonization Furnace

Table of Contents

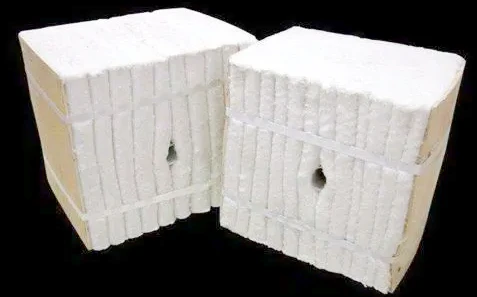

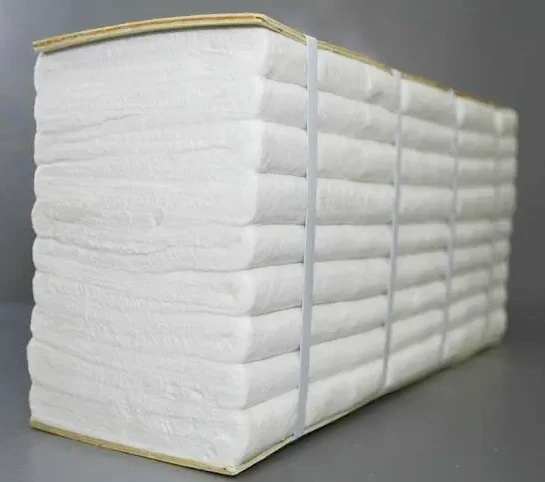

The improved carbonization system simplifies the process. The carbonization furnace is moved from underground to aboveground, and the refractory lining is changed from heavy to lightweight. Ceramic fibers are predominantly used as the lining material for the carbonization furnace.

1. Carbon Material Firing Process

1)Low-Temperature Preheating Stage:The carbon product is heated from room temperature to 200°C, with a maximum temperature not exceeding 350°C.

2)Medium-Temperature Transformation Stage (Pyrolysis and Polymerization Reaction): The temperature of the carbon product is between 200 and 700°C, and the temperature inside the kiln is approximately between 350 and 850°C. As the temperature rises, the decomposition rate of coal tar accelerates. During this stage, the binder undergoes carbonization, and a large amount of volatiles are expelled.

3)High-Temperature Carbonization Stage (Graphitization Stage): In this stage, the temperature of the carbon product ranges from 700°C to 1000°C, and the temperature inside the kiln is about 850°C to 1300°C. As the fired product reaches temperatures above 700°C, the rate of coal tar decomposition and volatilization slows down, and the carbonization of the binder is essentially completed.

The firing temperature in the third stage will be adjusted based on the different sintered carbon materials used. For example, for materials like carbon blocks, which do not require a graphitization stage, the firing temperature only needs to reach 1300°C. However, for materials like electrodes, which require graphitization treatment, the sintering temperature needs to be higher, around 1200°C. As for materials like carbon resistors, which require a high resistance, their firing temperature is relatively lower, only needing to reach 1000°C.

2. Different Refractory Fiber Materials Required for Carbonization Furnace at Different Temperature Ranges

1)Low-Temperature Preheating Stage: Standard ceramic fiber material

2)Medium-temperature Transformation Stage (Pyrolysis and Polymerization Reaction): High-purity ceramic fiber material

3)High-Temperature Carbonization Stage (Graphitization Stage): Zirconia-containing ceramic fiber materials or composite polycrystalline refractory fiber materials

Advantages of Using Ceramic Fiber Materials as Insulation Lining for Carbonization Furnace:

1)Lightweight with low heat absorption, being 1/20 of heavy refractory bricks and 1/10 of lightweight refractory bricks.

2)Ultra-low thermal conductivity, resulting in notable energy-saving effects

3)Easy and convenient construction without the need for drying and curing

4)Resistant to rapid heating and cooling