Application of Ceramic Fiber Blankets in Blocking Slag for Cast Steel

Table of Contents

1. The Importance of Slag Removal in Molten Steel

From the moment molten steel is tapped from the furnace until it is completely poured, the most critical operations are slag removal and purification, as well as slag blocking during pouring. This process involves high labor intensity, intolerable heat radiation, potentially impacting the casting quality. It also poses a high level of danger for workers in this position. Finding an easy and reliable solution to address these challenges in the pouring process is an urgent matter.

2. Characteristics of Using Ceramic Fiber Blankets for Slag Removal

The zirconia-containing alumina-silicate needled fiber blankets produced by Anchor Company can address this issue. The material is lightweight, soft, has an appropriate sintering temperature, strong slag gathering ability, excellent heat insulation and light-shielding effects, and is easy and safe to use. It possesses the following characteristics:

01. Anchor Company’s zirconia-containing ceramic fiber is a neutral insulation and slag gathering material, suitable for surface covering, slag gathering, slag removal, and slag blocking for molten steel with various chemical compositions.

02. The slag blocking ceramic fiber cotton is soft and can be easily torn or shredded into small pieces by hand, with low density (128Kg/m3).

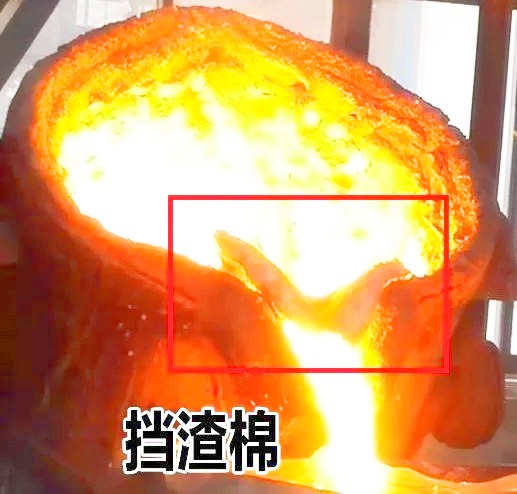

03. The ceramic fiber cotton block floats on the surface of the molten steel and will never adhere to the furnace wall. During pouring, all slag residues that float on the surface of the molten iron are strongly gathered around the ceramic fiber cotton.

04.During coverage, the ceramic fiber cotton used can be thin or thick, preventing light transmission and will not turn red. It provides excellent heat insulation. The harsh working environment for pouring workers exposed to heat radiation is improved, ensuring safety and ease.

05. Before pouring, the ceramic fiber cotton can be torn into thin slices of 5-10mm and applied around the pouring cup to prevent splashing of molten steel during pouring, which could potentially injure people or damage the mold (especially in lost foam and V method casting). if molten steel splashes on the sealing film during pouring, it is prone to burn through, causing air leakage or even box collapse. Zirconium-aluminum fiber cotton is used to protect the pouring cup or the area around the sprue for each box poured, ensuring safe production.

06. After pouring, the “residual cotton” that falls to the bottom of the ladle or is trapped at the mouth of the ladle can be easily cleared out of the ladle without any adhesion. When it is in the red temperature zone, it can be easily pulled out with an iron rod due to its soft texture.

07. Low cost to use