Ceramic Fiber Zirconium Blanket and Module Insulation Scheme for Car Kiln

Table of Contents

Car kiln Introduction

The car kiln belongs to an intermittent variable temperature kiln, mainly used for preheating steel ingots or workpiece heat treatment, thus it can be divided into car-type heating kiln and car-type heat treatment kiln. The furnace consists of a furnace chamber, a movable car, and a furnace door.

Differences in car kilns with zirconium ceramic fiber insulation scheme

- Insulation structure of car kiln heating furnace lining For car-type heating kiln insulation on the furnace roof, walls, and door: Use zirconium ceramic fiber modules with a thickness of 300mm; compensating blankets made of zirconium ceramic fiber blankets; backing blankets using high-purity ceramic fiber blankets with a thickness of 50mm.

- Car-type heat treatment kiln insulation For the furnace roof, walls, and door: Utilize zirconium ceramic fiber modules; the backing blankets use high-purity ceramic fiber blankets with insulation thicknesses of 30/50mm. The choice of insulation thickness and material depends on the heat treatment temperature.

Sealing treatment at the junction of furnace roof and walls

The junction between the furnace roof and walls is a weak area for lining, prone to air leakage or flame intrusion, reducing the insulation effect and affecting the lifespan of the lining. To prevent this area from forming through-holes, the wall-to-wall and wall-to-ceiling connections use a staggered connection method between ceramic fiber modules and ceramic fiber backing blankets. Moreover, to counteract the high-temperature shrinkage at the joint of the wall and top, a compensating gap is set up, utilizing zirconium modules and zirconium fiber blankets folded to maintain a compression ratio of over 30%, ensuring a high-temperature sealing effect in this area.

Anchor-technology's Ceramic Fiber Zirconium Blanket and Module

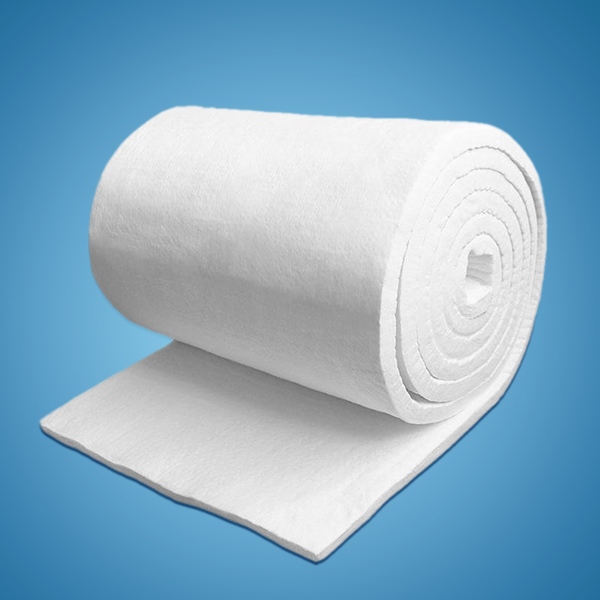

Anchor-technology’s Ceramic Fiber Zirconium Blanket is made of alumina, silica, zirconia, melted at high temperatures, needled, and has high tensile strength, low thermal conductivity, excellent insulation, with a maximum continuous working temperature of up to 1300℃.

Anchor-technology’s Ceramic Fiber Zirconium Module has the blanket folded, reinforced with boards and straps, with a density of up to 240kg/m3, low thermal conductivity, excellent insulation, with a maximum continuous working temperature of up to 1300℃.