Ceramic Fiber Insulation Scheme for RTO Furnace

Table of Contents

Description of RTO Furnace

RTO (Regenerative Thermal Oxidizer) is an environmental pollution control technology primarily used in industrial applications to treat exhaust gases before releasing them into the atmosphere. RTO is mainly employed to treat volatile organic compounds (VOCs), hazardous air pollutants (HAPs), and other pollutants emitted during industrial processes.

The RTO system passes contaminated air through a combustion chamber equipped with a heat recovery system. Inside this chamber, VOCs and other pollutants oxidize at high temperatures, typically between 1400°F to 1600°F (760°C to 870°C). The oxidized pollutants are transformed into carbon dioxide, water vapor, and heat.

What sets RTO apart is its regenerative design. It employs a ceramic bed filled with heat-absorbing material (usually ceramic media) that alternately captures and releases heat generated during combustion. This design allows the system to recover and reuse a significant amount of heat produced during oxidation. Compared to other thermal oxidation units, RTO is more energy-efficient.

Full Ceramic Fiber Insulation Scheme

Furnace Temperature: Maximum temperature in the upper combustion chamber is 850°C, and approximately 750°C in the lower heat storage chamber.

Insulation Effect: Utilizes ceramic fiber insulation materials to maintain an exterior wall temperature of not more than 60°C after insulation.

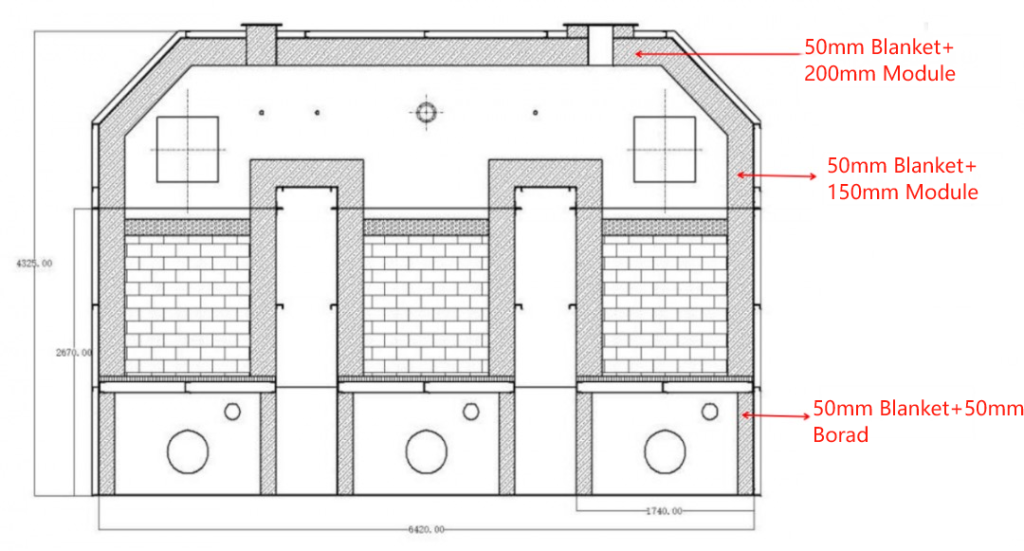

Insulation Scheme for Combustion Chamber:

The combustion chamber uses ceramic fiber as internal insulation material with a total thickness of 250mm, structured as follows: 200mm: 1260 Anchor-Tech ceramic fiber module; 50mm: 1050 ceramic fiber blanket (2 layers of 30mm compressed). Metal fixtures for ceramic fiber modules use 304 stainless steel.

Insulation Scheme for Heat Storage Chamber:

The heat storage chamber uses ceramic fiber as internal insulation material with a total thickness of 200mm, structured as follows: 150mm: 1260 Anchor-Tech ceramic fiber module; 50mm: 1050 Aladdin ceramic fiber blanket (2 layers of 30mm compressed). Metal fixtures for ceramic fiber modules use 304 stainless steel.

Insulation Scheme for Heat Storage Chamber Ductwork:

The lower ductwork of the heat storage chamber employs ceramic fiber as internal insulation material with a total thickness of 100mm, structured as follows: 50mm: 1260 Anchor-Tech ceramic fiber board; 50mm: 1050 Aladdin ceramic fiber blanket. Ceramic fiber installation fixtures use 304 stainless steel.

Fiber Surface Treatment:

The ceramic fiber module surface in the RTO furnace lining is coated twice with a curing agent, offering resistance to water vapor and high-speed flue gas flushing, prolonging the insulation lining’s lifespan.

Advantages of Using Full Fiber Insulation Scheme in Comparison to Traditional Fireproof Insulation Brick or Castables:

– Reduced overall weight of the RTO furnace, facilitating transportation.

– Enhanced overall insulation effectiveness due to the low thermal conductivity of ceramic fiber materials, preventing heat dissipation from the heat storage chamber to the furnace’s exterior, significantly reducing operating costs and extending the RTO furnace’s lifespan.

– Excellent thermal shock resistance of ceramic fiber insulation materials to withstand temperature fluctuations caused by periodic replacement of the inlet, ensuring the integrity of the furnace lining.

– The lightweight, high-temperature resistant ceramic fiber lining forms a completely airtight fire-resistant layer after the pre-compressed refractory module is installed and the packing band is removed, eliminating the need for expansion joints.

– Strong chemical stability: Ceramic fiber, comprising materials like aluminum oxide and silicon dioxide, does not react chemically with the volatile organic compounds (VOCs) or hazardous air pollutants (HAPs) present in the RTO furnace.

– Effectively reduces noise: Ceramic fiber is not only an excellent insulating refractory material but also a superior sound insulation material.