Ceramic Fiber Insulation Scheme for Mesh Belt Glass Annealing Furnace

Table of Contents

Overview of Mesh Belt Glass Annealing Furnace

The mesh belt glass annealing furnace is primarily used for glass product annealing, gold baking, and the heating process for trademarks and gold edges. The process involves placing glass products on the mesh belt, which then conveys them through the furnace from the inlet, heating them. Following this, the products are molded, gradually cooled in a cooling chamber, and finally retrieved from the outlet, completing the entire heat treatment process.

Insulation Scheme for Mesh Belt Glass Annealing Furnace

The operating temperature of the glass annealing furnace varies from 150°C to 520°C, depending on the type of paint being baked, with a maximum temperature not exceeding 650°C. Electric heating is commonly used. The dimensions of the small annealing furnaces range from 400 to 1300mm in width, 200 to 400mm in height, and 10m to 60m in length. A novel insulation structure for mesh belt glass annealing furnaces can utilize a combined insulation structure of Anchor-Tech ceramic fiber boards and Anchor-Tech ceramic fiber blankets.

Introduction to Anchor-Tech Ceramic Fiber Boards and Ceramic Fiber Blankets

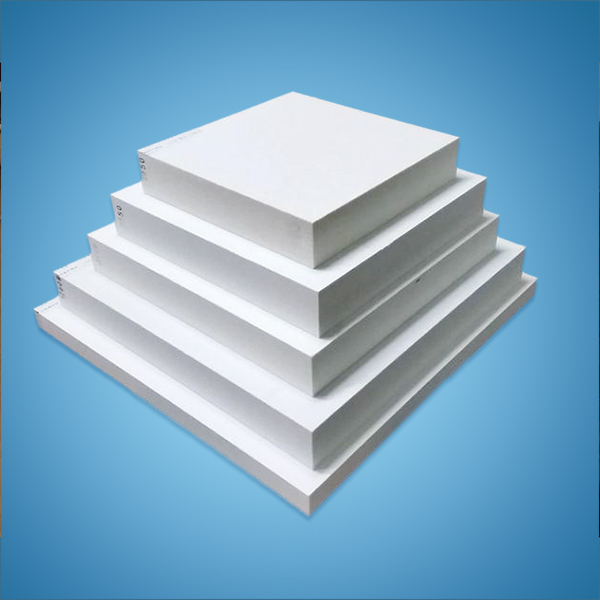

Anchor-Tech high-alumina ceramic fiber boards are produced using continuous production and advanced process technology on a streamlined production line. With a density of 350Kg/m³, it can withstand temperatures up to 1400°C, and has a long-term working temperature of 1100°C. It can be embedded with heating wires or closely adhered to heating rods. The boards feature a smooth surface, precise dimensions, good flexibility, easy cutting, and excellent insulation performance.

Anchor-Tech ceramic fiber blankets with low shot particle content as low as 8% (typical value) have a light mass with a density of 128Kg/m³. They can withstand temperatures up to 1260°C, with a long-term working temperature of 1050°C, low heat capacity, and are suitable for long-term use as insulation materials in glass annealing furnaces, offering a long service life.