Ceramic Fiber High-Temperature Insulation Solution for Petrochemical Reforming Furnace

Table of Contents

I. Overview of Reforming Furnace

Catalytic reforming is a crucial part of the refining process, aimed at enhancing oil quality. The reaction in the reforming furnace provides heat. There are two types: side-fired box furnaces and bottom-fired reforming furnaces. Presently, many reforming furnaces are of combined type, with tube temperatures around 210°C and chamber temperatures around 900°C.

II. Ceramic Fiber Insulation Structure for Reforming Furnace

Example: Radiant section of a side-fired reforming furnace with a segmented ceramic fiber lining:

Insulation at the roof of the catalytic reforming furnace’s radiant chamber: Lining Thickness: 280/300mm Structure: 250mm of 1400-type low-zirconia ceramic fiber modules + 30/50mm of 1260-type standard ceramic fiber blanket Anchoring Material: S304 stainless steel

Insulation on the upper part of the walls of the catalytic reforming furnace: Lining Thickness: 250-270mm Structure: 220mm of 1400-type low-zirconia ceramic fiber modules + 30/50mm of 1260-type standard ceramic fiber blanket Anchoring Material: S304 stainless steel

Insulation at the lower part of the side walls at the end of the radiant section of the catalytic reforming furnace (around 7 meters above the furnace bottom where the burners are): Lining Thickness: 300mm Structure: 250mm of 1400-type low-zirconia ceramic fiber modules + 50mm of 1260-type standard ceramic fiber blanket Anchoring Material: S310 stainless steel

III. Technical Advantages of Anchor-Tech Ceramic Fiber Production

01 Chemical Stability: The chemical properties of the ceramic fiber lining are stable. It is not corroded by acids, alkalis, water, oil, steam, and does not react with lead, aluminum, or copper.

02 No Need for Oven Treatment: No oven procedures required (such as curing, drying, baking, complicated oven processes, and protective measures in cold weather). After construction, the lining can be used immediately, saving time and cost.

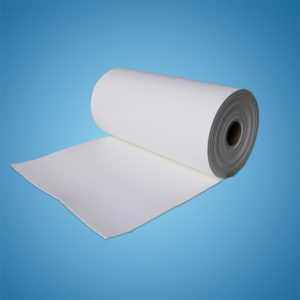

03 Production Process Advantage: Blanket-type fiber products utilize the spinning and needling process. The fibers are long, uniform in diameter, possess high tensile strength, expand considerably, resist airflow erosion, and exhibit excellent thermal stability with minimal shrinkage at high temperatures.

04 Extremely Low Shot Particle Content: Anchor-Tech ceramic fiber blankets have a shot particle content as low as 8%, resulting in a low thermal conductivity and excellent insulation performance.