Ceramic Fiber Insulation Solution for Mesh Belt Furnaces

Table of Contents

I. Overview of Mesh Belt Furnaces

High-temperature mesh belt furnaces are sintering furnaces where parts are continuously conveyed inside the furnace using Mafir-protected mesh belts. They are primarily used in the sintering of powder metallurgy products, reduction of metal powders, and preheating, firing, or heat-treating processes for electronic products in protective atmospheres or air, suitable for small parts processing. Maximum furnace temperature: 1150℃ (metallurgy), 750℃ (catalysis). The entire equipment comprises the furnace body, the mesh belt transmission system, and a temperature control system. The furnace body consists of the inlet section, preheating section, sintering section, slow cooling section, water cooling section, and outlet section. The mesh belt transmission system includes high-temperature resistant belts and transmission devices.

II. Insulation Structure of Mesh Belt Furnaces

Firing temperature: 480 ℃ to 620℃; Maximum temperature: 750 ℃

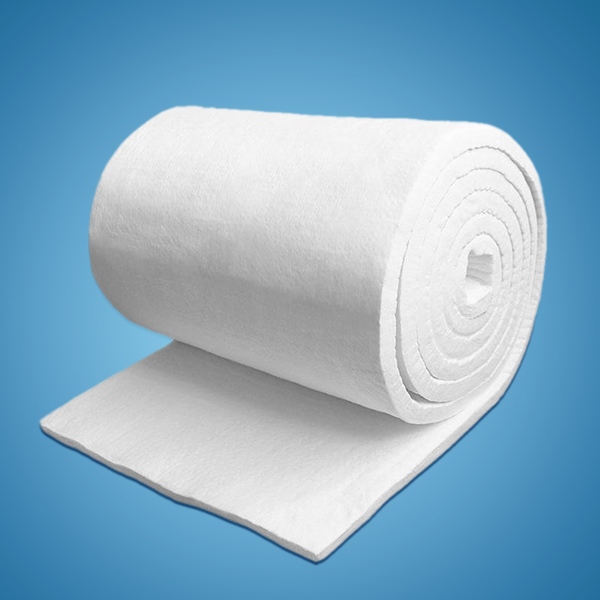

Insulation material selection for mesh belt furnaces: Standard ceramic fiber modules combined with standard ceramic fiber blankets

Furnace walls: Anchor-Tech standard ceramic fiber modules + 30mm Anchor-Tech standard ceramic fiber backing blankets

Furnace roof: 300mm Anchor-Tech standard ceramic fiber modules + 50mm Anchor-Tech standard ceramic fiber backing blankets

III. Advantages of Using Ceramic Fiber as Insulation Material in Mesh Belt Furnaces

- Insulation in mesh belt furnaces allows easy matching of suitable insulation thickness for the furnace roof, maintaining similar heat dissipation between the furnace walls and roof, ensuring consistent external surface temperatures.

- Mesh belt furnaces utilize full fiber lining, reducing heat storage and thermal inertia in the furnace walls, shortening heating times, enhancing control precision, decreasing surface temperature rises in the furnace shell, reducing heat loss, and improving thermal efficiency, thereby achieving high-efficiency energy conservation.

- The entire furnace lining in mesh belt kilns adopts a fiber structure with excellent refractory fiber construction, offering good insulation, thereby minimizing temperature on the furnace roof steel structure to prevent deformation.