Table of Contents

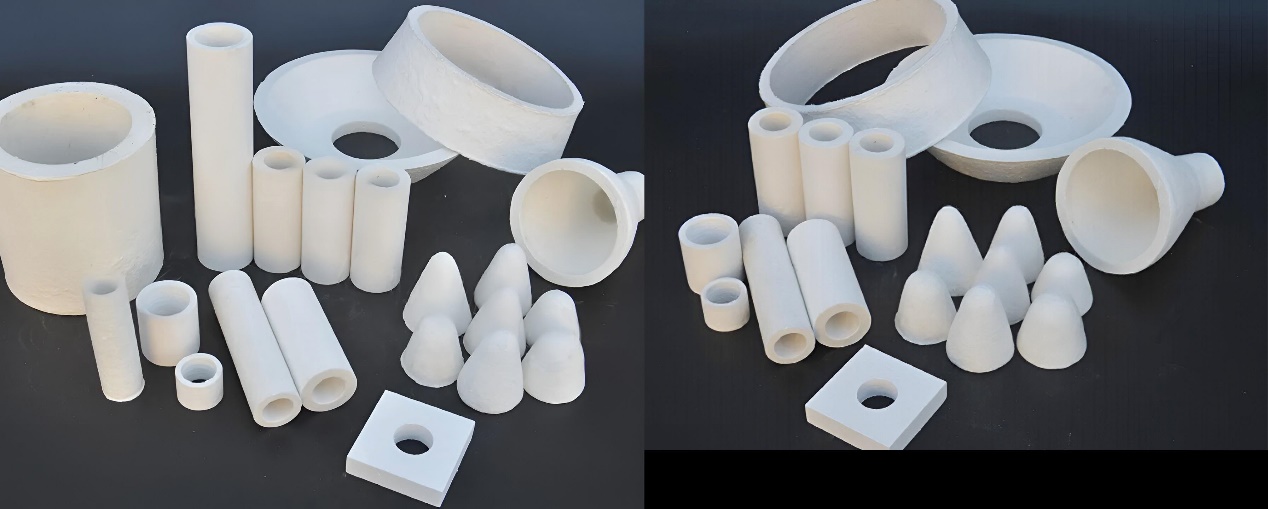

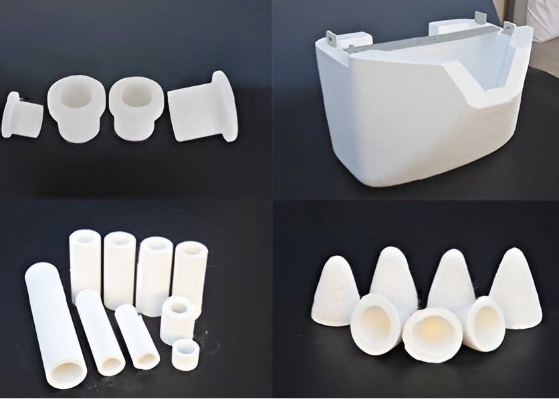

Anchor-Tech Ceramic Fiber Special-shaped Parts

Many customers have misunderstandings about ceramic fiber special-shaped parts and do not understand the situation and knowledge of ceramic fiber special-shaped parts. Today, Anchor-Tech will share with you the relevant content of ceramic fiber special-shaped parts, so that everyone can have a deep understanding of ceramic fiber special-shaped parts. In this way, you can be aware of it when buying and using ceramic fiber special-shaped parts. I hope it will be inspiring and helpful to you.

Many customers have misunderstandings about ceramic fiber special-shaped parts and do not understand the situation and knowledge of ceramic fiber special-shaped parts. Today, Anchor-Tech will share with you the relevant content of ceramic fiber special-shaped parts, so that everyone can have a deep understanding of ceramic fiber special-shaped parts. In this way, you can be aware of it when buying and using ceramic fiber special-shaped parts. I hope it will be inspiring and helpful to you.

1. Product description

Anchor-Tech uses high-quality ceramic fiber cotton as raw material and is vacuum formed.

The characteristic of this product is that it is a special-shaped product with superior high-temperature performance, rigidity and self-supporting strength. Each product requires a special mold according to its form and size . According to the performance requirements of the product, different binders and additives are selected to meet usage requirements.

Typically used in high temperature sealing, insulation and casting consumables.

2. Product features

(1) It has the ability to give various shapes, high compressive strength, high temperature resistance, suitable density, low shrinkage, lightweight and easy to transport , etc.;

(2) Temperature range is 900℃ to 1500℃ ;

(3) Unburnt materials can be easily cut or machined. During use, ceramic fiber special-shaped parts have good resistance to wear and peeling , and are not wetted by most molten metals ;

(4) Due to its excellent thermophysical properties, convenient installation and durability, the application of ceramic fiber special-shaped parts can significantly reduce energy consumption .

3.Main products

* Vacuum-formed special-shaped products of various sizes and shapes can be produced, including rectangular, round, tubular, conical, semicircular, dome-shaped and square box-shaped, etc.

* Most special-shaped products can be produced according to customer requirements, and some special-shaped products can also be kept in stock for customers, such as casting caps and sleeves for the non-ferrous metal industry, vacuum-formed fire-seeking holes for the petrochemical industry , etc.

4. Production process

Drawing confirmation or sample specification confirmation – mold making – sample molding – sample testing – mass production – drying and airing – packing – delivery – customer use