Table of Contents

Good Product for Kiln Energy Saving – Ceramic Fiber Veneer Block

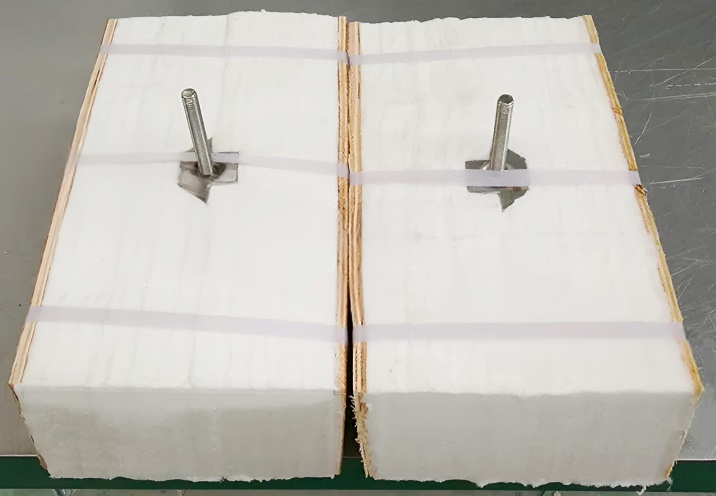

Anchor-Tech Ceramic Fiber Veneer Blocks

Anchor-Tech ceramic fiber veneer blocks are mainly used for refractory linings of old kilns. They are a form of ceramic fiber modules. This product requires professional technicians to fold or cut ceramic fiber blankets and stack them in layers. They are made into veneer blocks according to a certain pressure. The installation method is mainly to bond the veneer blocks to refractory bricks or castable wall linings through refractory adhesives .

Saving effect of Anchor-Tech ceramic fiber veneer block

1. The use of veneer block is effective for the transformation of kilns with traditional refractory lining (refractory brick or castable structure). This is because the veneer block is pasted on the refractory brick or castable lining of the kiln without changing the existing furnace body. Through its own low thermal conductivity and excellent thermal insulation performance, it reduces the surface temperature of the refractory brick or castable, thereby extending the life of the furnace lining, reducing heat loss, and improving product quality.

2. The modification of veneer blocks has low investment, simple construction, outstanding energy-saving effect, and is recognized by the majority of industrial kiln users. However, it should be noted that the thickness of the veneer block is not always proportional to the energy efficiency. The most important thing to balance the economic effect and energy-saving effect is to reasonably choose the thickness of the fiber veneer block .

times that of a 10mm thick fiber veneer layer , which can significantly reduce the heat flow through the fiber layer to the refractory brick wall. However, when the fiber veneer layer thickness is greater than 75mm, increasing the fiber veneer layer thickness will only slightly reduce the heat loss of the furnace wall. Therefore, the thickness of the ceramic fiber module veneer layer should be 50mm.