Table of Contents

Thermal Insulation Mechanism of Ceramic Fiber Aluminum Foil Blanket

In order to ensure the safe operation of thermal equipment and reduce heat loss, and to achieve the goal of saving energy and reducing product costs, thermal equipment must be treated with insulation according to different requirements and specifications. Therefore, a new type of ceramic fiber aluminum foil blanket came into being. This blanket has excellent thermal insulation and radiation properties, can effectively reduce heat loss, and has the characteristics of light weight, softness, and easy installation. Using this blanket can greatly improve the efficiency and reliability of the equipment, while also reducing maintenance costs and extending the life of the equipment.

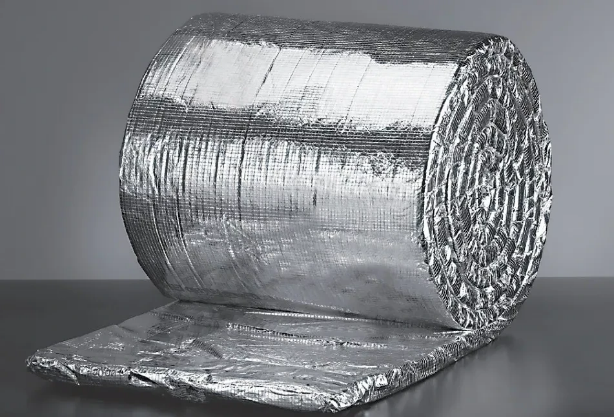

Anchor-Tech Ceramic Fiber Aluminum Foil Blanket

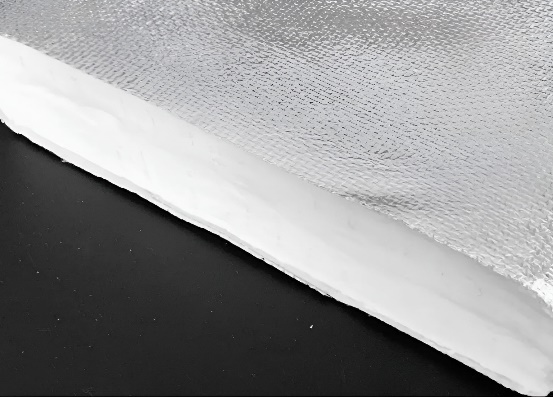

Anchor-Tech ceramic fiber aluminum foil blanket is a combination product that uses a special adhesive to bond Anchor-Tech ceramic fiber blanket and metal aluminum foil into an integrated structure . It has the characteristics of light weight, good insulation effect, high density, corrosion resistance, good thermal shock resistance, high tensile strength, and easy construction and maintenance . It is particularly suitable for the insulation and heat preservation of high-temperature thermal equipment and heating pipes with strict requirements on insulation and energy saving effects.

Thermal insulation mechanism of ceramic fiber aluminum foil blanket

Generally speaking, there are three main ways for thermal equipment to dissipate heat: conduction, convection and radiation . The aluminum foil blanket , with its unique structure, weakens the three heat dissipation pathways and reduces heat loss.

1. Weakening of conduction heat dissipation

The heat from the heat source must first pass through the fiber blanket , and the heat dissipation by conduction can only be carried out along the direction of the fiber rod. However, the fiber interweaving of the ceramic fiber blanket has no directionality, which invisibly prolongs the heat transfer path and weakens the heat conduction. In addition, the porosity of the ceramic fiber blanket is 93%, and 80% of the contact between the fibers is point contact. The point contact and high porosity further weaken the heat conduction and increase the thermal resistance of the conduction heat dissipation.

2. Weakening of convection heat dissipation

Ceramic fiber blanket is very high. The gas is divided by the fiber into many small pore compartments that are almost motionless. The pressure in the dispersed multi-pore compartments is certain. This air pressure will form a dense shield together with the solid fiber (forming shielding air pressure), hindering the invasion of hot air flow and weakening heat loss. At the same time, due to the high density of aluminum foil, it directly hinders the convection of gas.

3. Weakening of radiation heat dissipation

Ceramic fiber itself is a white, smooth reflector, which has a good radiation effect on heat; at the same time, the metal aluminum foil in the aluminum foil needle-punched blanket is opaque and smooth, with a mirror reflection mechanism, and the heat rays are reflected by the aluminum foil. This barrier significantly weakens the radiation heat transfer. Therefore, the aluminum foil blanket has a double-layer weakening mechanism for radiation heat dissipation, and the effect is significant.

Application of aluminum foil blanket

aluminum foil covered needle-punched blanket has good thermal insulation and energy-saving effects. It is mainly used in the thermal insulation layer of the lining of industrial heating furnaces and boiler equipment in petrochemical and metallurgical industries, the external thermal insulation of power steam pipelines, the thermal insulation layer of aerospace equipment, the fire-fighting interlayer of ships, the interlayer of the construction industry, and the thermal insulation of daily necessities.