Table of Contents

Electrically heated shell baking furnace insulation solution

1. Overview of Shell Forming Furnace

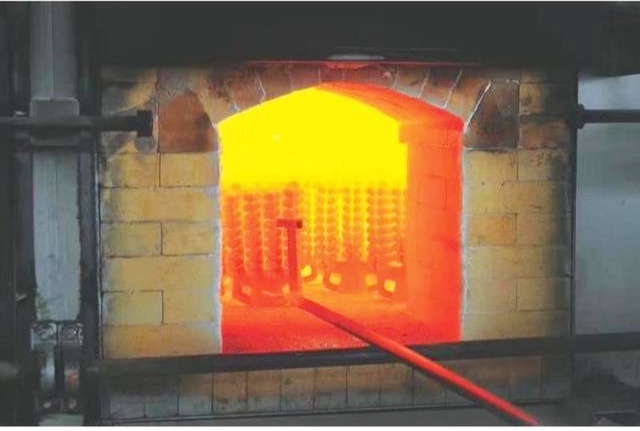

The shell baking furnace is a gas-fired bottom-drawn trolley flame furnace, which adopts the characteristics of imported industrial furnace equipment . Compared with the original conventional furnace type, it has the advantages of significantly reduced energy consumption, uniform temperature, clean environment, and convenient maintenance. The furnace uses the flame to spray heat upward, and after encountering the arc top, it rotates and discharges downward to the middle flue, effectively controlling the furnace temperature uniformity and the utilization rate of thermal energy.

The furnace is mainly composed of furnace body (including furnace lining), furnace door, furnace car, combustion system, smoke exhaust system, sealing, temperature control and recording and other main components.

2. Insulation of electrically heated shell baking furnace

There are three types of mold shell baking furnaces for precision casting according to the heating source: one is gas, heavy oil, crude oil type mold shell baking furnace; one is gas-fired mold shell baking furnace; one is electric heating mold shell baking furnace. According to the different heating sources, the lining of the mold shell baking furnace is also divided into many types. The lining of the heavy oil type mold shell baking furnace is generally built with refractory bricks or castables. The lining of the gas-fired mold shell baking furnace is built with polycrystalline composite fiber modules . The electric heating mold shell baking adopts high-purity ceramic fiber modules.

The lining of the electrically heated shell roasting furnace adopts a full fiber insulation structure built with Anchor-Tech high-purity ceramic fiber modules, which has an energy saving rate 40% higher than that of a brick furnace.

The operating temperature of the electrically heated shell baking furnace is generally between 1100℃ and 800℃, and the maximum temperature will not exceed 1200℃.

Anchor-Tech high-purity fiber module products are white, made of high-purity ceramic fiber blanket folded and compressed into an accordion shape. The regular size is 300*300*300mm, which can be customized according to customer needs. The long-term working temperature is 1100℃.

3. Benefits of using ceramic fiber insulation

Anchor-Tech ceramic fiber modules have fine fibers, high elasticity, low impurities, few slag balls, stable performance, and good thermal and chemical stability.

The ceramic fiber module has excellent elasticity. The module is in a pre-pressed state. After the shell baking furnace lining is built, the expansion of the module makes the lining seamless and can compensate for the shrinkage of the fiber lining to improve the insulation performance of the fiber lining. The overall performance is excellent.

The ceramic fiber module has excellent elasticity. The module is in a pre-pressed state. After the shell baking furnace lining is built, the expansion of the module makes the lining seamless and can compensate for the shrinkage of the fiber lining to improve the insulation performance of the fiber lining. The overall performance is excellent.