Anchor-Tech 1500℃ type ceramic fiber composite module

Types of 1500℃ ceramic fiber composite modules

Chrome module

It is made of folded chromium-containing fiber blankets and has good high-temperature stability. The module density is ≥230Kg/m3.

It is made of folded chromium-containing fiber blankets and has good high-temperature stability. The module density is ≥230Kg/m3.

Chromium + zirconium composite module

The outer layer of the hot surface is a chromium-containing blanket , and the inner layer is a zirconium-containing blanket . This form gives full play to the respective advantages of chromium-containing and zirconium-containing blankets and can save some material costs. However, the difficulty of production and processing increases. Module bulk density ≥220Kg/m3

Chrome+Felt composite module

Sliced module : taking advantage of the high temperature resistance of chrome blankets and the low shrinkage and good resilience of Felt products. Reduce the occurrence of shrinkage gaps. Module bulk density ≥220Kg/m3

Performance index parameters

|

project |

unit |

chrome blanket |

1500 Felt |

|

Classification temperature |

℃ |

1500 |

1500 |

|

Test weight |

Kg/m3 |

128 |

140 |

|

tensile strength |

Kpa |

≥60 |

≥55 |

|

burn out |

% |

– |

≤6.0 |

|

heating wire shrinkage |

% |

≤3 |

≤2.5(1400℃×24h) |

|

chemical composition |

A1203 |

≥42 |

– |

|

A1203+Si02+Cr203 |

≥99.1 |

– |

|

|

Fe203 |

≤0.2 |

– |

|

|

K20+Na20 |

≤0.25 |

– |

|

|

Module density |

Kg/m3 |

220 |

|

|

Module size deviation |

Compression direction (mm) |

-10~0 |

|

|

Insulation direction (mm) |

0~10 |

||

|

Cutting direction (mm) |

-3~+3 |

||

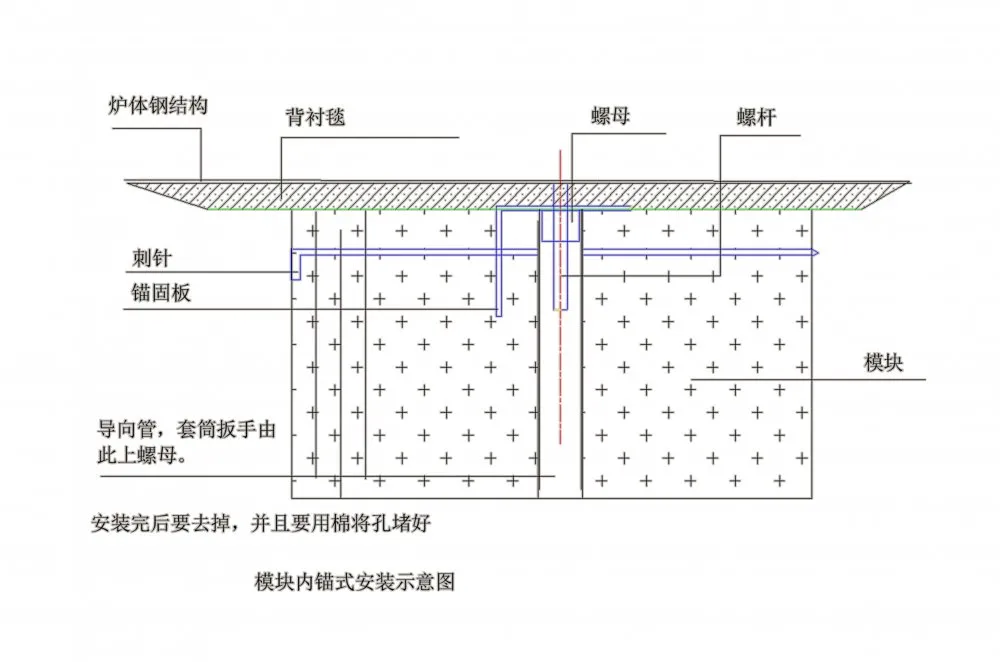

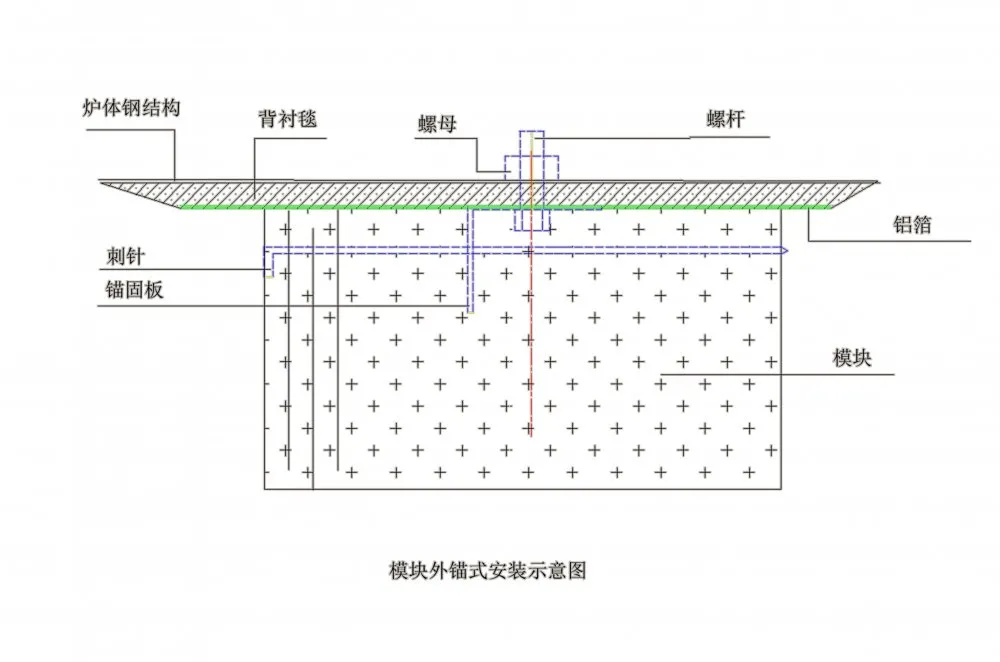

Types of module anchors and their installation methods

Schematic diagram of anchor installation within the module

Schematic diagram of anchor installation within the module

Module external anchor installation diagram

Module external anchor installation diagram

1500 composite module usage examples display

1500 composite module usage examples display

Enhancement of 1500 composite modules

In order to improve the service life of the furnace lining , we will upgrade the 1500 composite module. The main measure is to treat the surface or expansion joints of the furnace lining with high-temperature coatings .

Particularly recommended application areas

1. Forging heating furnace

2. Coking oven door

3. Furnace types for 1250C working conditions in the metallurgical industry