Table of Contents

Anchor-Tech Ceramic Fiber Blanket Insulation Solutions for Blast Furnace Vaults

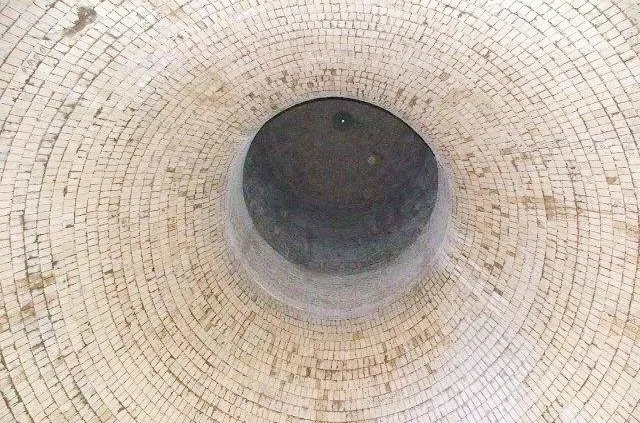

1. Blast furnace vault introduction

Blast furnace is one of the main supporting equipment of iron making plant. Due to the advantages of good technical and economic indicators, simple process, large production volume, high labor productivity and low energy consumption, the iron produced by this method accounts for the vast majority of the world’s total iron production. At present, the temperature of advanced modern blast furnaces can reach 1000-1300℃. The vault lining is under great pressure due to its own production method.

2. Difficulties in heat preservation of blast furnace vault

(1) It is difficult to build the insulation layer at the top of the ball, and it is very difficult to construct the upward face, making it difficult to ensure the construction quality;

(2) The furnace lining requires a combination of several thermal insulation materials, but the joints between thermal insulation materials are uneven, the gaps are of different sizes, and the thermal insulation effect is not ideal;

(3) Unlike the furnace wall insulation lining, the top ceramic fiber blanket and other insulation materials are always subjected to vertical downward tensile force regardless of whether they are in a wet or dry state , and the service life of the furnace lining is short.

(4) The sealing effect between the thermal insulation materials and the refractory bricks is not good. The surface temperature of the hemispherical top of the hot blast furnace is high, the heat dissipation loss is large, the furnace skin steel plate is prone to oxidation and corrosion, and the anti-corrosion coating on the steel shell and top of the furnace is prone to burn.

3. Solution

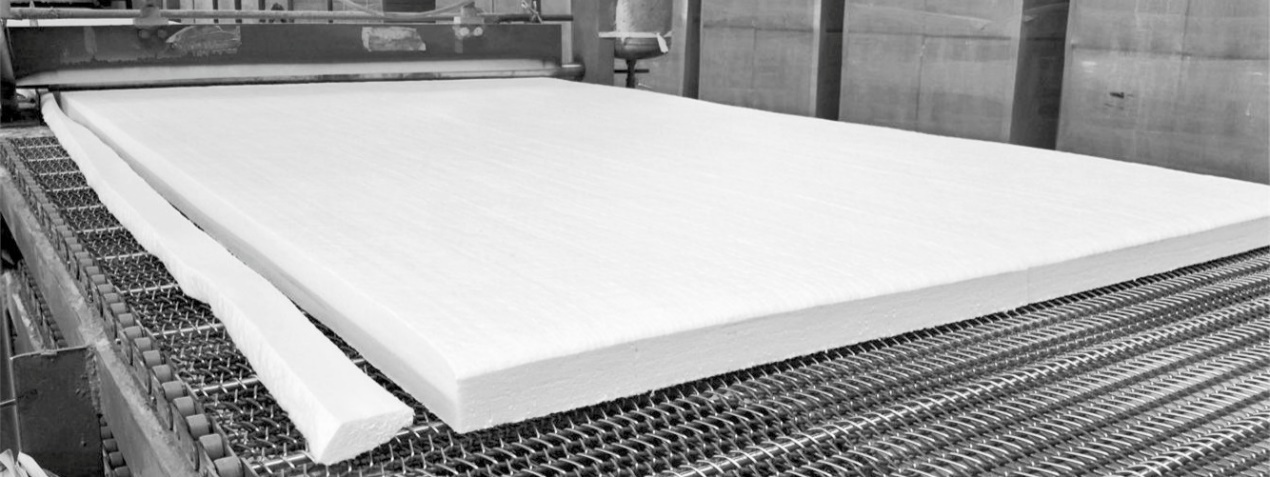

The Anchor-Tech ceramic fiber blanket cotton + adhesive spraying method can be used, which does not require manual installation and effectively extends the service life of the furnace lining while improving the thermal insulation effect of the blast furnace top.