Table of Contents

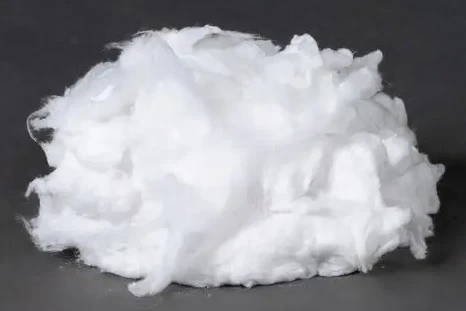

Anchor-Tech Ceramic Fiber Bulk

01. Anchor- Tech Ceramic Fiber Bulk Production Process and Characteristics

* Ordinary ceramic fiber bulk: It is made of hard clay clinker as raw material, melted in a resistance furnace, and produced by blowing or spinning into fibers.

* High-purity and high-aluminum ceramic fiber wool: Made from high-purity alumina silica powder as raw material, it is melted in a resistance furnace and produced by blowing or spinning into fibers.

* Zirconium-containing ceramic fiber wool: It is made from zirconium oxide aluminum silica powder as raw material, melted in a resistance furnace, and produced by blowing or spinning into fibers.

02. Product Categories

Ordinary ceramic fiber bulk, standard ceramic fiber bulk, high-purity ceramic fiber bulk, high-aluminum ceramic fiber bulk, and zirconium-containing ceramic fiber bulk.

03. Product Application

Industrial kilns, heating devices, high-temperature pipeline linings, power boilers, gas turbines and nuclear power insulation, chemical industry high-temperature reaction equipment and heating equipment linings, building materials industry glass tank kiln insulation, high-rise building fire protection, insulation, stress relief insulation for welded parts, stress relief insulation for special-shaped metal castings, kiln doors, roof insulation, high-temperature filtration materials.

Ceramic fiber wool has the function of fire resistance and heat insulation. This material is generally suitable for use in high-temperature areas. In the past, it was only used in turbine cylinders and boiler wall linings in thermal power plants. However, in recent years, when various design and use units select thermal insulation materials, when the temperature exceeds 400°C, most of the inner layer of the thermal insulation layer uses ceramic fiber wool products.