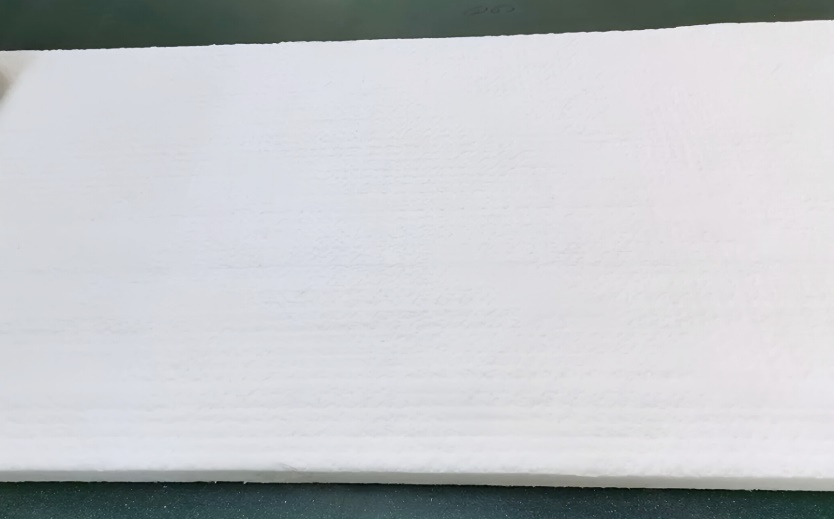

Anchor-Tech Ceramic Fiber Zirconium Blanket

Anchor-Tech ceramic fiber zirconium blanket , literally means a blanket made of ceramic fiber wool containing zirconium oxide .

Origin: Ceramic fiber is a common refractory insulation material that can meet the insulation requirements of most high-temperature thermal equipment. The temperature resistance of ceramic fiber mainly depends on the content of alumina. According to the purity of alumina, ceramic fiber can be divided into ordinary type, standard type, high-purity type, high-aluminum type, zirconium-containing type, chromium-containing type and other types, and the refractory temperature rises from 900℃ to 1500℃.

Among them, the aluminum oxide content of high-aluminum ceramic fiber is 52%-55%, which is the highest aluminum content among ceramic fibers. However, zirconium oxide is chemically inactive and has the properties of high melting point, high resistivity, high refractive index and low thermal expansion coefficient, making it an important high-temperature resistant material. The introduction of zirconium oxide components has increased the classification temperature of ceramic fibers from 1400℃ of high-aluminum ceramic fibers to 1430℃.

Base on the content of zirconium oxide in ceramic fiber , it can be divided into zirconium aluminum (low zirconium) type and zirconium-containing type . The zirconium oxide content of zirconium aluminum (low zirconium) type is 5%-7%, the classification temperature is 1400℃, and the use temperature is higher than that of aluminum type ceramic fiber blanket; the zirconium oxide content of zirconium-containing type is ≥15%, and the classification temperature is 1430℃.

Base on the content of zirconium oxide in ceramic fiber , it can be divided into zirconium aluminum (low zirconium) type and zirconium-containing type . The zirconium oxide content of zirconium aluminum (low zirconium) type is 5%-7%, the classification temperature is 1400℃, and the use temperature is higher than that of aluminum type ceramic fiber blanket; the zirconium oxide content of zirconium-containing type is ≥15%, and the classification temperature is 1430℃.

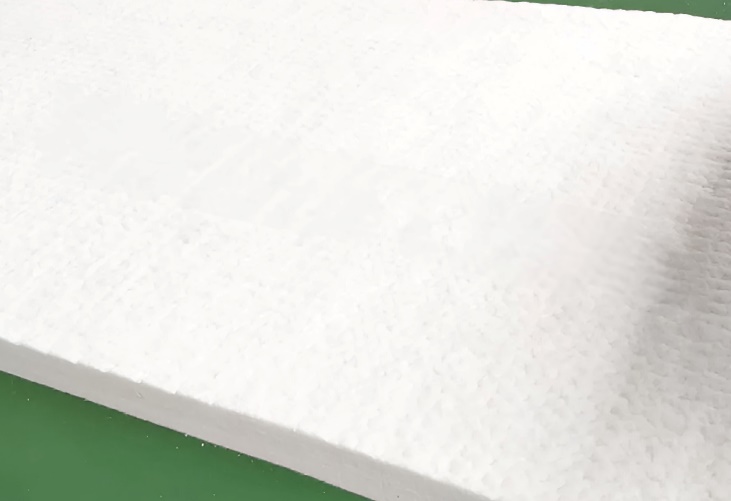

In addition to being made into ceramic fiber modules from zirconium-containing ceramic fiber blankets , zirconium -containing ceramic fiber products can also be made into zirconium ceramic fiber boards , zirconium-containing ceramic fiber papers and other related products.

Zirconium ceramic fiber ceramic fiber blankets has greatly broadened the application field of ceramic fibers. Previously, the problem that high-temperature equipment such as rolling furnaces, ladles, cracking furnaces, and pusher heating furnaces could not use ceramic fibers due to limitations has now been solved. The advantages of zirconium-containing ceramic fibers such as fire resistance, heat insulation, insulation, consumption reduction, long life, and cost savings have been unanimously praised by the majority of users. It is no exaggeration to say that the emergence of zirconium-containing ceramic fiber modules has promoted the replacement and renewal of the entire kiln industry.