Anchor-Tech Chrome Ceramic Fiber Insulation Fire Blanket

Introduction of chromium-containing ceramic fiber blanket

containing alumina -silica-chromium oxide are very suitable for use in high-temperature furnaces. Since the Cr2O3 content in the fiber is greater than 2.5%, it blocks the growth and sintering of crystals in the contact parts between fibers, and the operating temperature increases by 30 to 50%. ℃, effectively filling the temperature gap between zirconium-containing fibers and alumina fibers.

Anchor-Tech Chrome Ceramic Fiber Blanket Performance Indicators

| Classification temperature | 1500℃ | ||

| color | green | ||

| chemical composition | |||

| Al2O3 | 43% | ||

| SiO2 | 54.5% | ||

| Cr2O3 | 2.0-3.8% | ||

| Fe2O3 | 0.15% | ||

| Na20+K20 | 0.25% | ||

| Test weight | |||

| 96Kg/m3 | 128Kg/m3 | 160Kg/m3 | |

| tensile strength | |||

| 128Kg/m3 | 70KPa | ||

| 160Kg/m3 | 80KPa | ||

| Heating line changes: Keep warm for 24 hours | |||

| 1400℃ | <3% | ||

| Specific heat value | |

| 1090℃ | 1.13 KJ/Kg.K |

| General product specifications | |

| length | 3600—7200 mm |

| width | 610mm, 1220mm |

| thickness | 13mm, 20mm, 25mm, 30mm |

| Thermal Conductivity | 128Kg/m3 |

| 200℃(W/m.K) | 0.05 |

| 400℃(W/m.K) | 0.09 |

| 600℃(W/m.K) | 0.15 |

| 800℃(W/m.K) | 0.20 |

| 800℃(W/m.K) | 0.27 |

TC UK R&D laboratory test results

| project | Detection | result |

| color | green | |

| Chemical composition (% wt ) | SiO2 | 54.5 |

| A12O3 | 43 | |

| CaO | 0.21 | |

| MgO | <0.05 | |

| ZrO2 | <0.05 | |

| Cr2O3 | 3.2 | |

| Alkalies | <0.05 | |

| Fe2O3 | <0.05 | |

| Other | 0.2 | |

| Thermal properties | Line shrinkage 24hrs(%) | |

| 1150℃ | 2.5 | |

| 1200℃ | 2.6 | |

| 1250℃ | 2.7 | |

| 1300℃ | 2.7 | |

| 1350℃ | ||

| 1400℃ | 3.0 | |

| 1450℃ | 4.6 | |

| 1500℃ | 4.6 | |

| Thickness direction line shrinkage | ||

| 1150℃ | 18.3 | |

| 1200℃ | 30.4 | |

| 1250℃ | 32.0 | |

| 1300℃ | 34.2 | |

| 1350℃ | ||

| 1400℃ | 39.1 | |

| 1450℃ | 44.3 |

Thermal conductivity (W/m. K) | Average temperature 200℃ | 0.051 |

| Average temperature 400℃ | 0.076 | |

| Average temperature 600℃ | 0.124 | |

| Average temperature 800℃ | 0.197 | |

| Average temperature 1000℃ | 0.295 | |

| Average temperature 1200℃ | 0.417 | |

| Physical properties | Length(mm) | 7280 |

| Width(mm) | 620 | |

| Thickness(mm) | 24.9 | |

| Net weight(kg) | 14.82 | |

| Bulk weight(kg/m³) | 132 | |

| Average ball content | 55 | |

| Typical slag ball division | ||

| 45μm to 75μm | 11.8 | |

| 75μm to 125μm | 19.6 | |

| 125μm to 200μm | 12.8 | |

| 200μm to 250μm | 4.2 | |

| 250μm to 300μm | 1.6 | |

| 300μm to 600μm | 3.9 | |

| ITINN | 11 |

Heating line change comparison

| Temperature℃×24 hours | Contains zirconium | Contains chromium |

| 1150 | 1.25 | 2.51 |

| 1200 | 1.68 | 2.62 |

| 1250 | 1.90 | 2.71 |

| 1300 | 2.36 | 2.66 |

| 1350 | 2.00 | 3.85 |

| 1400 | 2.64 | 3.22 |

From the changes in the heating line , it can be seen that the zirconium content is less than the chromium content, but from the observation and analysis of the samples after burning in the laboratory , the state of the chromium ceramic fiber blanket after 1300°C is better than that of the zirconium-containing product . The chromium ceramic fiber blanket is still in the fiber state and the product is elastic ;

chromium ceramic fiber blanket have begun to pulverize , and the elasticity of the product is reduced. After 1400°C, the zirconium-containing ceramic fiber blanket sample had light yellow granular precipitates, and the fibers were seriously pulverized.

Comparison of states after calcination

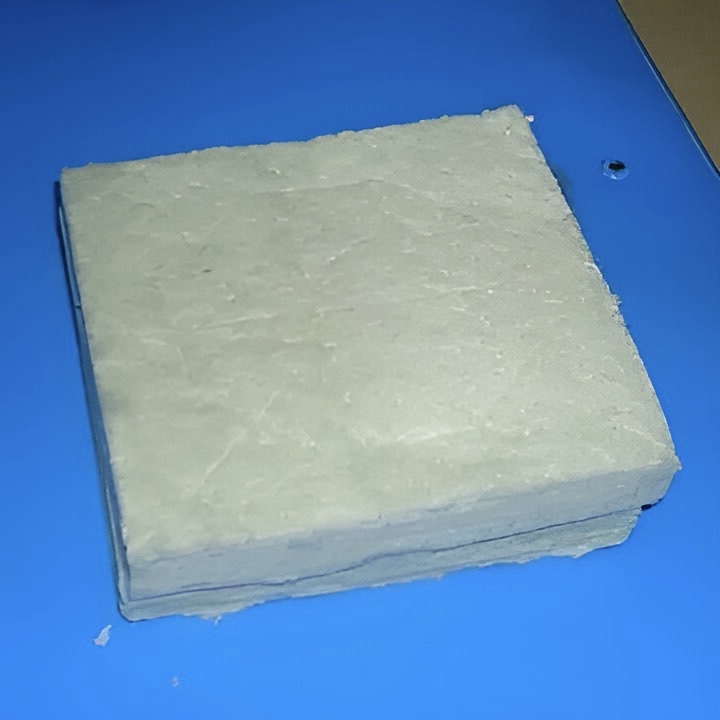

zirconium ceramic fiber blanket after calcining at 1400°C × 24 hours. The surface fibers have begun to pulverize and a hard crust appears.

chromium ceramic fiber blanket after calcining at 1400°C×24 hours. There is no powdering phenomenon on the surface fibers and the fiber condition is in good condition.

in conclusion

- Since the temperature of chromium-containing fibers during fiber formation is higher than the fiber-forming temperature of zirconium-containing fibers, the diameter of chromium-containing fibers is smaller and the thermal conductivity is good . However, during the initial crystallization, the fibers will produce stress changes, which will cause the fibers to bend and the diameter will increase. Small, the greater the bending, so the initial linear shrinkage reflected on the surface is greater for chromium-containing fibers than for zirconium-containing fibers;

- Since the high-temperature stability of Cr2O3 is better than that of Zr2O3, Cr2O3 has a strong blocking ability during the growth of grains, thus ensuring that the hardening and powdering of chromium-containing fibers at high temperatures is better than that of zirconium-containing fibers and has a longer service life. long ;

- As long as the fiber has sufficient elasticity under high temperature conditions, the shrinkage of the fiber can be compensated through material compounding, furnace lining design and construction techniques;