Table of Contents

Anchors-Good Partner of Ceramic Fiber Modules

Anchors are an important part of ceramic fiber furnace linings, and there are many types of anchors. The selection of anchors should be comprehensively considered based on the industrial kiln structure, furnace temperature, and environmental atmosphere.

Today, Anchor-Tech will give you some knowledge about anchors to facilitate the installation of ceramic fiber modules in the future.

1. Overview of ceramic fiber module anchors

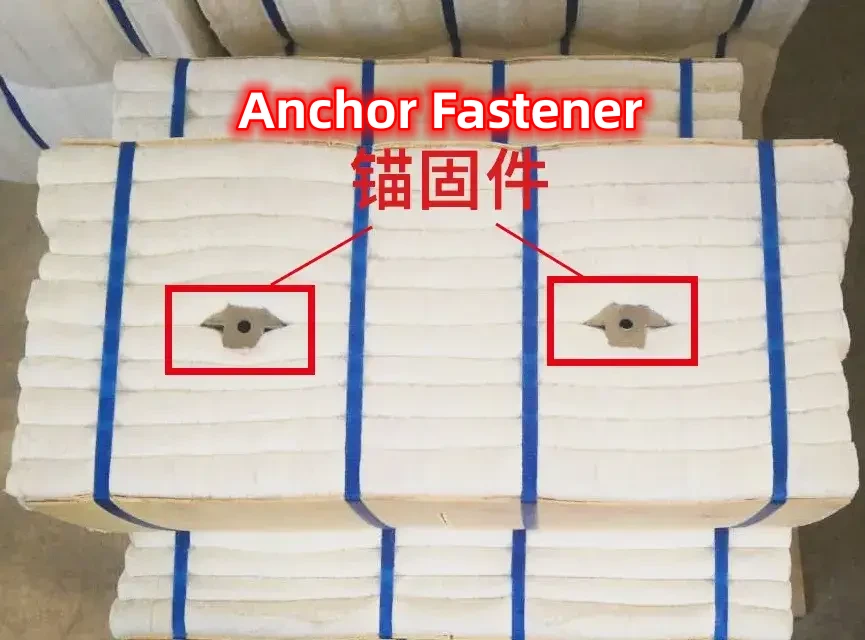

Anchors are commonly used components in ceramic fiber module construction. Their function is to fix the integral ceramic fiber module lining or prefabricated components in a certain position to resist static load, thermal stress, mechanical rotation or vibration, and prevent refractory material construction from occurring. The collapse of the material also helps to disperse the shrinkage evenly and avoid the formation of large and concentrated cracks. The selection of anchors should follow the principles of easy, fast, firm and reliable installation .

Anchors are commonly used components in ceramic fiber module construction. Their function is to fix the integral ceramic fiber module lining or prefabricated components in a certain position to resist static load, thermal stress, mechanical rotation or vibration, and prevent refractory material construction from occurring. The collapse of the material also helps to disperse the shrinkage evenly and avoid the formation of large and concentrated cracks. The selection of anchors should follow the principles of easy, fast, firm and reliable installation .

2. Heat-resistant steel anchors are mainly classified into the following categories

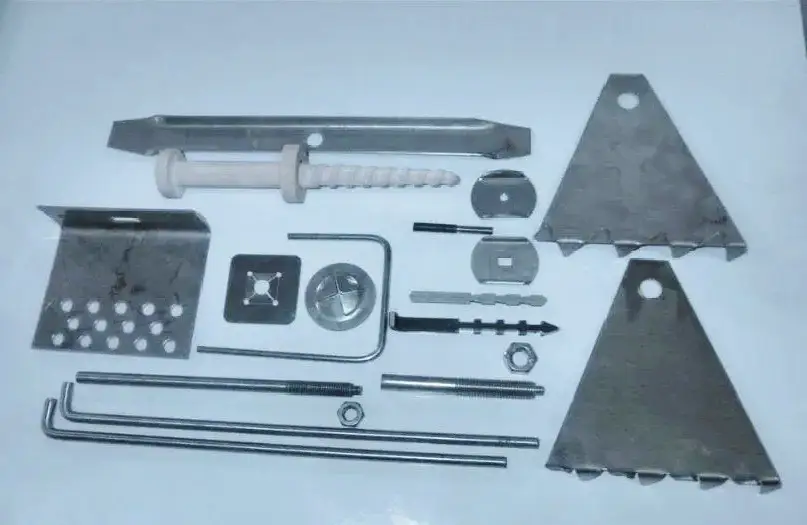

Ceramic fiber module prefabricated anchors : angle iron anchors, diamond anchors, butterfly anchors, overhead anchors, corner anchors;

Ceramic fiber folding block anchors : herringbone anchors, quick cards, rotating cards, threading bars, screw nuts, threading bars, U-shaped nails, V- shaped nails, etc .;

3. Divided according to high temperature resistance strength

* 201 stainless steel anchors, recommended operating temperature below 600°C

* 304 stainless steel anchors, recommended operating temperature 600-1100℃

* 310 stainless steel anchors: recommended operating temperature below 1200°C

* 316 heat-resistant steel anchors, recommended use temperature below 1400°C