Table of Contents

Application of ceramic fiber products in the automotive industry

For cars, people now pay more attention to the feeling of driving or safety in case of accidents, such as space, preventive facilities, noise, and heat insulation. Commonly used ceramic fiber products in the field of automobile manufacturing mainly include Anchor-Tech ceramic fiber blankets , ceramic fiber modules, ceramic fiber paper, etc. Below Anchor-Tech briefly introduces the ceramic fiber products used in the automobile manufacturing stage and different parts of the car.

Application

01. When modifying automotive metal parts or shaping and eliminating stress in the automotive body structure, a heat treatment furnace is needed, which can be a trolley heat treatment furnace or a hanging heat treatment line. In this stage, Anchor -Tech ceramic fiber modules and blankets are needed as the lining of the metal parts heat treatment furnace.

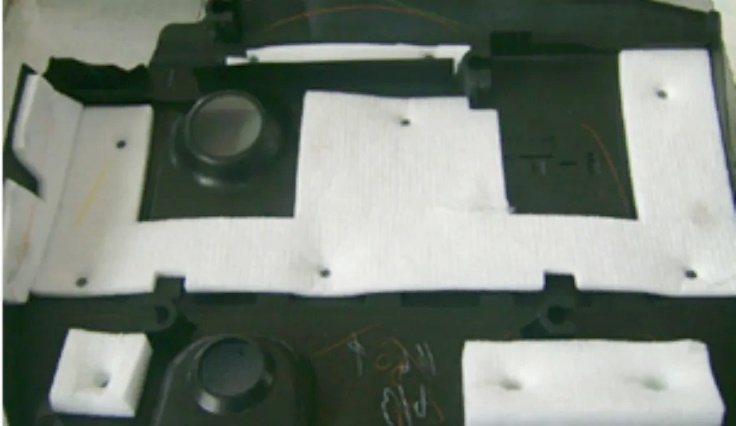

02. Use Anchor-Tech ceramic fiber paper or thin ceramic fiber blanket to reduce the noise entering the cab. The noise of the hood operation will increase with the increase of vehicle speed, power, engine roar and other large noises, and will enter the cockpit through various media. Laying a certain amount of engine insulation cotton on the hood can effectively reduce the transmission of noise generated by engine operation through the air channel. The sound insulation cotton on the upper and lower hood covers of the engine can also absorb part of the noise. The exhaust pipe is part of the engine exhaust system. The exhaust system mainly includes the exhaust manifold, exhaust pipe and muffler. The one-way catalytic converter that is generally used to control engine pollutant emissions is also installed in the exhaust system. The exhaust pipe generally includes the front exhaust pipe and the rear exhaust pipe.

03. The inner layer of the door panel should be covered with Anchor-Tech ceramic fiber paper or thin ceramic fiber blanket . In almost all car models, the four doors cover a large area, second only to the roof and chassis. It will have direct contact with the air during driving. In addition to the designers designing a certain rounded shape for the door panel to reduce the noise caused by wind resistance, car manufacturers also know that as long as more car sound insulation cotton is covered on the inner side of the door panel, this wind noise can be efficiently absorbed. The modification shop disassembled the interiors of various models and found that only the cars with higher prices on the market have this kind of sound insulation cotton material on the inner layer of the door panel.