The Impact of Shots on Ceramic Fiber Modules

The Impact of Shots on Ceramic Fiber Modules Table of Contents In the process of spinning raw materials into ceramic fibers, industry professionals refer to the unconverted particles as “shots”. Generally, those with a particle diameter larger than 0.212mm and a bulk density ranging from 2800 to 3200 Kg/m³ are categorized as shots. 1. Generation […]

Insulation Solution for Ceramic Fiber in Hot-Dip Galvanizing Furnace

Insulation Solution for Ceramic Fiber in Hot-Dip Galvanizing Furnace Table of Contents Hot-dip galvanizing technology is a high-energy-consuming production process. With China advocating energy conservation, energy-saving insulation work in the hot-dip galvanizing industry has become crucial. In continuous hot-dip galvanizing production lines, the annealing furnace for hot-dip galvanizing accounts for about sixty to seventy percent […]

Effects of Various Performance Factors of Ceramic Fiber Board on Its Use

Effects of Various Performance Factors of Ceramic Fiber Board on Its Use Ceramic fiber boards are processed using a wet vacuum forming process. This type of product has higher strength compared to fiber blankets and vacuum-formed felts, making it suitable for high-temperature applications with requirements for structural strength. Anchor Company will now explain how various […]

Refractory Ceramic Fiber Lining for Flat-Top Tunnel Kiln – Insulation Solution

Refractory Ceramic Fiber Lining for Flat-Top Tunnel Kiln – Insulation Solution Table of Contents 1. Overview of Flat-Top Tunnel Kiln The pulverized coal brick kiln is a tunnel kiln used to heat and fire wet brick blanks primarily made from coal gangue or shale, producing finished bricks. The length of a pulverized coal brick kiln […]

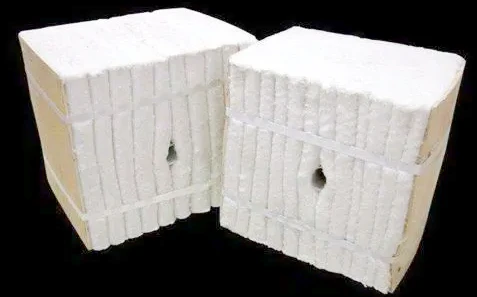

What is the Best Structure for a Full Ceramic Fiber Furnace Lining?

What is the Best Structure for a Full Ceramic Fiber Furnace Lining? Table of Contents Currently, common industrial furnaces mostly use full ceramic fiber linings, except for furnaces with high wear and tear, high wind speeds, or complex chemical compositions. The choice of ceramic fiber is based on its high-temperature resistance and light weight. Additionally, […]

Why Ceramic Fiber Modules Should Not Be Used at Excessive Temperatures?

Why Ceramic Fiber Modules Should Not Be Used at Excessive Temperatures? Ceramic fiber modules, known as the best partner of industrial kilns, are familiar to all, and it is well understood that material selection based on temperature (operating temperature) is a fundamental principle. But why is this the case? As a high-temperature refractory insulation product, […]