Ceramic Fiber Insulation Solution for Mobile Tunnel Kiln

Table of Contents

I. Overview of Mobile Tunnel Kiln

The mobile tunnel kiln, also known as the ring tunnel kiln, or simply the ring kiln, is a firing brick process system designed with a reverse thinking method: the bricks remain stationary while the kiln moves. Its core technology involves a circular kiln body moving along a circular track. The unfired bricks are placed on the circular kiln bottom between the kiln’s front track, where the kiln progresses, incorporating the bricks for drying, preheating, firing, and cooling processes. After the kiln moves, the finished bricks can be unloaded on the exposed kiln bottom at the kiln’s open end.

The insulation along the length of the tunnel kiln is divided into preheating, firing, and cooling zones.

The most prominent feature of “mobile tunnel kiln insulation” is the immobility of the bricks while the kiln moves.

The process includes brick stacking, drying, preheating, firing, insulation, cooling, and brick unloading in sequence.

II. Ceramic Fiber Insulation Structure for Mobile Tunnel Kiln

Firing Zone Temperature Range: 950°C – 1150°C (usually not reaching 1150°C); Insulation Thickness: 300mm Ceramic Fiber Modules (with reinforced compensatory blankets) + 30/50mm Laid Blanket + 3mm Surface Curing Agent; Material Selection: High-alumina ceramic fiber modules for the kiln roof + standard fiber blankets, high-alumina ceramic fiber modules for walls + standard ceramic fiber blankets. Anchoring Material: S304 diamond-shaped anchoring fixtures.

Preheating and Cooling Zones Temperature Range: 300°C – 950°C; Insulation Thickness: 250mm Ceramic Fiber Modules (with reinforced compensatory blankets) + 30/50mm Laid Blanket + 3mm Surface Curing Agent; Material Selection: Standard ceramic fiber modules for the kiln roof + standard ceramic fiber blankets, standard ceramic fiber modules for walls + ordinary ceramic fiber blankets. Anchoring Material: S304 diamond-shaped anchoring fixtures.

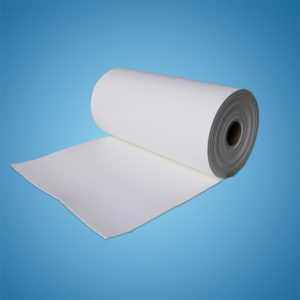

Flue (Moisture Discharge, Waste Heat Utilization) Temperature Range: 100°C – 300°C; Alumina-silicate ceramic fiber insulation thickness: 100mm ceramic fiber blanket + steel wire mesh + tar paper + fiberglass cloth + asphalt paint; Material Selection: Ordinary ceramic fiber blanket + medium-alkali fiberglass cloth.

III. Surface Curing of Ceramic Fiber Insulation Lining

Surface curing treatment for ceramic fiber insulation lining: Apply 2 coats of Anchor-Tech high-temperature surface curing agent on the module surface to resist moisture and high-speed airflow, significantly extending the lifespan of the kiln’s fiber lining.