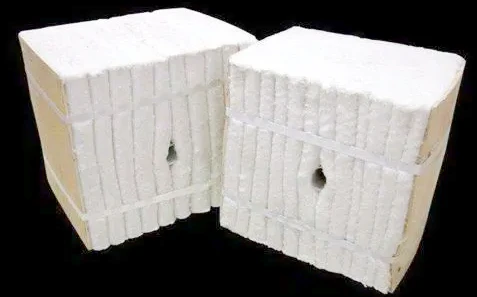

Anchor Company’s Ceramic Fiber Module Quality System and Application Effect

Anchor Company’s ceramic fiber modules are primarily used in various industrial furnaces and heating equipment linings. While the production of modules may seem simple, if not paid attention to or if details are overlooked, it can easily lead to quality issues, affecting installation and potentially causing significant problems in future use. So, how does Anchor Company ensure the quality of ceramic fiber modules?

1.Starting from the raw materials of the modules. Anchor Company uses their own-produced ceramic fiber blankets to ensure quality from the source while reducing costs to benefit customers.

2.In addition to meeting customer requirements, Anchor Company continuously monitors the quality of ceramic fiber products in real-time to ensure they meet national standards.

3.Anchor Company provides a one-stop system service from pre-sales to after-sales, and provide users with a worry-free and labor-saving experience.

Ceramic fiber modules have excellent resistance to wind erosion. The maximum wind erosion resistance of traditional layered fiber linings at 900°C is 10 m/s, while the maximum wind erosion resistance of fiber module linings is greater than 30 m/s. If prefabricated fiber modules contain inorganic binders, their wind erosion resistance can reach up to 50 m/s.

Ceramic fiber modules are widely used in various industries:

- Petrochemical industry: Furnace lining insulation

- Metallurgical industry: Kiln lining insulation

- Building materials industry (ceramics, glass, etc.): Furnace lining insulation

- Heat treatment industry: Furnace lining insulation

- Other industrial kiln lining insulation.

With the advancement of energy-saving and emission reduction initiatives, the renovation of brick-lined tunnel kilns is imminent. Ceramic fiber has received high praise for its excellent insulation performance in the ceiling insulation of brick-fired tunnel kilns.

Application Effect of Ceramic Fiber Modules

The pre-compression of ceramic fiber modules can compensate for shrinkage at high temperatures. This not only reduces the thermal shrinkage of the fiber lining but also, compared to traditional layered fiber linings, increases the operating temperature by more than 50°C under the same conditions.

Ceramic fiber modules have a simple structure and are easy to install, which greatly saves working time. When repairing the ceramic fiber lining, there is no need for extensive dismantling. Simply replacing the damaged sections of ceramic fiber modules can quickly restore production.