Insulation Solution of Anchor-Tech Ceramic Fiber Modules as Thermal Insulation Material in Scrap Steel Continuous Preheating Furnace

Table of Contents

I. Overview of Scrap Steel Continuous Preheating Furnace

- An effective method to increase the scrap steel ratio in steelmaking is through scrap steel preheating. The scrap steel continuous preheating furnace is a continuous production line similar to a mesh-belt industrial furnace, where scrap steel is preheated outside the steelmaking furnace, creating a continuous feeding mode that can increase the scrap steel ratio to 30-40%.

- Maximum furnace temperatures: 1100°C (at the burner), 800°C (in the preheating section).

- The entire system consists of three major parts: the insulation furnace set, a mobile conveying system, and a control system. The furnace comprises feeding, preheating, sintering, slow cooling, water cooling, and discharging sections.

- During the conveying process, converter gas is burned directly to heat the materials, improving energy utilization and heating efficiency. When applied to converters, it matches the production rhythm, actively controls capacity and temperature.

II. Insulation Solution for Scrap Steel Continuous Preheating Furnace

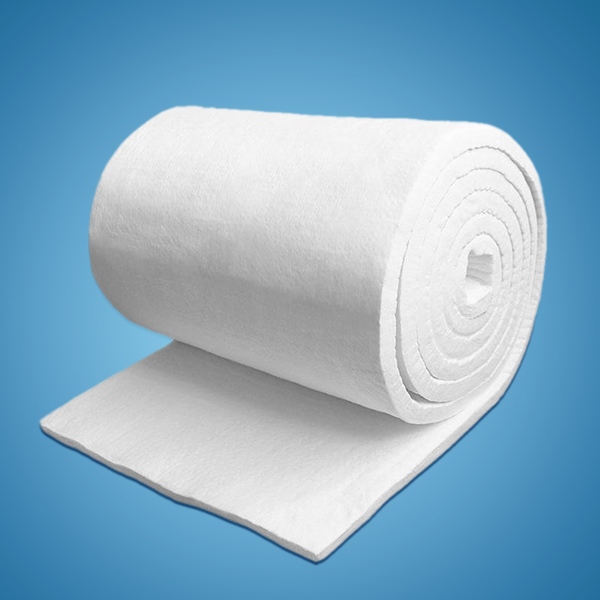

- Scrap steel at 800°C: 270mm thick low-zircon ceramic fiber modules combined with 30mm thick standard ceramic fiber blankets for insulation.

- Scrap steel at 500°C: 270mm thick standard ceramic fiber modules combined with 30mm thick standard ceramic fiber blankets for insulation.

III. Insulation Advantages of Anchor-Tech Ceramic Fiber Modules

- The insulation of the scrap steel preheating system is designed to easily match the appropriate insulation thickness for the furnace top, maintaining consistent heat dissipation from the furnace walls and top, resulting in a uniform outer surface temperature.

- The insulation device of the scrap steel preheating system uses an all-fiber furnace lining to reduce heat storage and thermal inertia of the furnace walls, shorten the heating time, improve control precision, lower the temperature rise on the furnace shell surface, reduce heat losses, and enhance thermal efficiency, achieving efficient energy-saving goals.

- The furnace chamber insulation of the scrap steel preheating system adopts an all-fiber structure, with well-laid refractory fibers, providing excellent insulation and minimizing the temperature of the furnace top steel structure to reduce deformation.