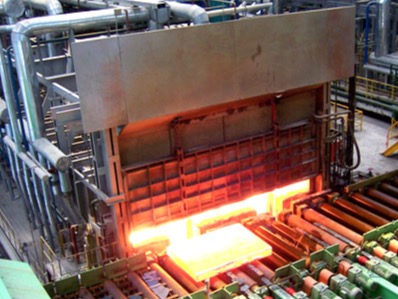

Application of Chromium Ceramic Fiber Modules in Forging Furnaces

Conventional ceramic fiber modules have struggled to meet the demands of forging furnace operations.

Application of Ceramic Fiber in Metallurgical and Mechanical Industry Furnaces

Application of Ceramic Fiber in Metallurgical and Mechanical Industry Furnaces Table of Contents Ceramic fiber, also known as aluminum silicate fiber, is a refractory material specifically designed for various high-temperature, high-pressure, and wear-prone environments. It boasts several advantages such as lightweight, high-temperature resistance, low thermal conductivity, excellent insulation properties, non-toxicity, among others. Its outstanding […]

Application of Ceramic Fiber in Insulation Pits

Application of Ceramic Fiber in Insulation Pits Table of Contents What are Insulation Pits Insulation pits are essential auxiliary facilities in steel mills used primarily to reduce the temperature loss of hot billets. The surroundings of the insulation pit consist of a bottom plate made of reinforced concrete and pad irons. The pit walls are […]

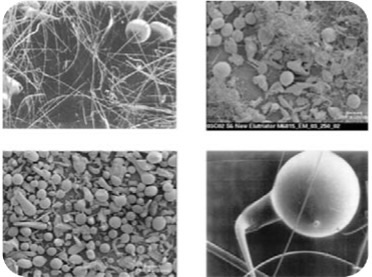

The difference between spinning process and blowing process for ceramic fiber

The difference between spinning process and blowing process for ceramic fiber Table of Contents When it comes to the production process of ceramic fibers, the vast majority of ceramic fiber products are made using the spinning (spun) process. As for the blowing (blown) process, it might not be well understood by most people. So, what […]

What are ceramic fiber shot particle?

What are ceramic fiber shot particle? Table of Contents When we talk about ceramic fiber products, the term “shot particle” is always mentioned, indicating that shot is a significant indicator for ceramic fibers. So, what exactly are shot particle? Shot particle refers to spherical particles that do not form fibers during the production process. […]

The Importance of Installation and Construction of Ceramic Fiber Module

The Importance of Installation and Construction of Ceramic Fiber Module Table of Contents The installation process and construction quality of ceramic fiber modules are the crucial first steps in determining the lifespan of refractory fiber linings. It is a highly significant aspect. If the chosen refractory ceramic fiber modules and other products are used at […]