Table of Contents

Three benefits and advantages of ceramic fiber blanket for muffle furnace

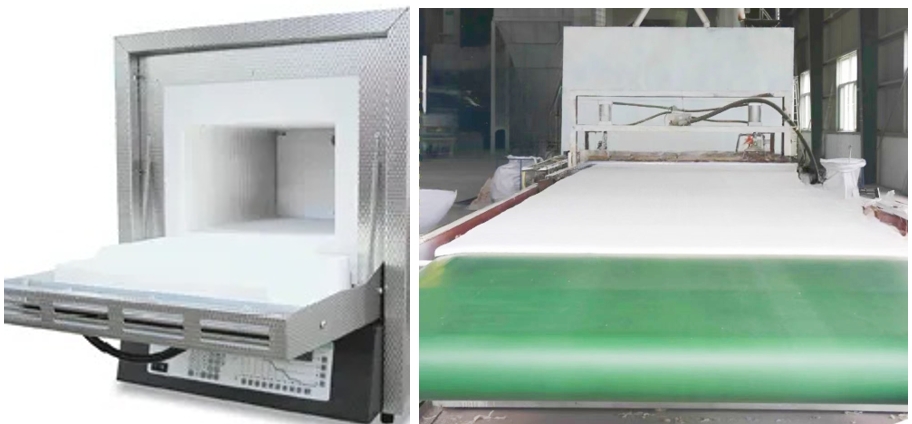

Muffle furnace is a universal heating equipment, which can be divided into box furnace, tube furnace and crucible furnace according to its appearance. It is mainly used for sample pretreatment in laboratories of colleges and universities and scientific research institutes, melting test in metallurgical laboratories, heat treatment annealing, quenching, etc. The muffle furnace is wrapped with a full fiber furnace chamber, and a ceramic fiber blanket can be placed as its insulation material. Today, Anchor-Tech will show you the three benefits and advantages of ceramic fiber blankets for muffle furnaces .

1. Rapid heating

Conventional low-temperature furnaces can heat up from room temperature to 1000°C in less than 30 minutes; 1700°C high-temperature furnaces can heat up from 100°C to 1700°C in 90 minutes.

2. High efficiency and low energy consumption

Equipped with air outlet holes and exhaust pipes , it is beneficial to replenish fresh oxygen and accelerate the test. According to user requirements, air inlet holes can be set and inert gas protection devices can be added to reduce the oxidation of samples.

Due to the use of ceramic fiber insulation materials, the heating and insulation effects have been greatly improved, so there is a big difference in energy saving compared to older furnaces. The power of a conventional small experimental furnace is only 2-3kw, and the power of a 20/30L cavity muffle furnace is only 7.5kw.

3. Light weight

The organizational structure of ceramic fiber muffle furnace insulation materials determines its lighter characteristics.

Due to the use of a new type of ceramic fiber furnace, the heat preservation effect is good. After rising to 1000℃ and maintaining it for 1 hour, the shell surface temperature is about 45-55℃ depending on the use environment.