What are ceramic fiber shot particle?

Table of Contents

When we talk about ceramic fiber products, the term “shot particle” is always mentioned, indicating that shot is a significant indicator for ceramic fibers.

So, what exactly are shot particle?

- Shot particle refers to spherical particles that do not form fibers during the production process. Shot particle with a diameter >0.212mm and a bulk density between 2800 and 3200kg/m3 are considered as shot.

- The generation of shot particle during fiber production is unavoidable, regardless of the spinning or blowing methods used.

- Shot particle does not exhibit the properties of fibers. It has a lower specific surface area, hence it is not effective in thermal insulation.

- The thermal conductivity of ceramic fiber products already factors in the influence of shot particle.

Impact of Shot particle Content on Ceramic Fiber Products:

The quality of ceramic fiber products is primarily judged based on aspects such as chemical composition, fiber diameter, fiber length, shot content, linear shrinkage rate, and thermal conductivity. Among these, shot particle content is an important performance indicator.

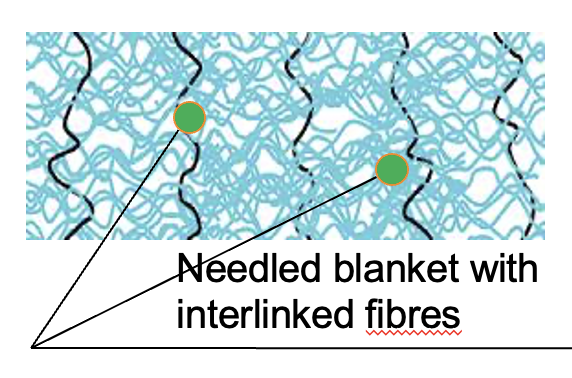

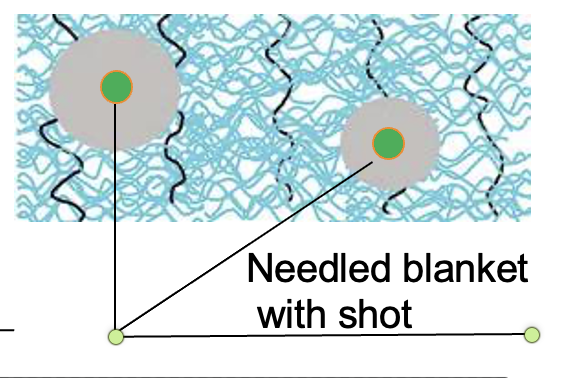

Reducing the thermal insulation performance of ceramic fiber products:

High shot particle content implies an abundance of crystalline particles inside the ceramic fiber modules, leading to a deterioration in the structural integrity of fiber cotton. This results in increased voids and enhanced convective heat transfer, thereby increasing the overall thermal conductivity and decreasing thermal insulation performance.

Decreasing the strength of ceramic fiber products:

The presence of shot particle particle alters the original arrangement structure of fiber cotton, enlarging the gaps between them, thereby reducing the strength of ceramic fiber modules, product durability, and electrical insulation properties.

Poor energy-saving effects, damaging user interests:

Excessive shot content will reduce the overall energy-saving performance of ceramic fiber products, increase internal consumption, and harm user interests.

Hence, a lower shot particle particle content is better.

Anchor-Technology's product advantages related to shot particle content:

GBT16400 Insulation Alumina Silicate Fiber and Fiber Products | (Shot particle diameter >210μm) ≤20.0% |

GBT3003 Refractory Ceramic Fiber and Products | (Shot particle diameter >212μm )≤25.0% |

Anchor-Technology’s RCF Series Products | (Shot particle diameter >212μm )≤8% |

Anchor-Technology’s AES Bio-Soluble Series Products | (Shot particle diameter >212μm) ≤6 |