What is the Best Structure for a Full Ceramic Fiber Furnace Lining?

Table of Contents

Currently, common industrial furnaces mostly use full ceramic fiber linings, except for furnaces with high wear and tear, high wind speeds, or complex chemical compositions. The choice of ceramic fiber is based on its high-temperature resistance and light weight. Additionally, a ceramic fiber lining effectively reduces the surface temperature of the furnace, minimizes fuel consumption losses, improves product quality and production yield, and extends the lifespan of the furnace.

As for the structure of the ceramic fiber lining in the kiln, it tends to lean towards a combination of ceramic fiber modules and blankets.

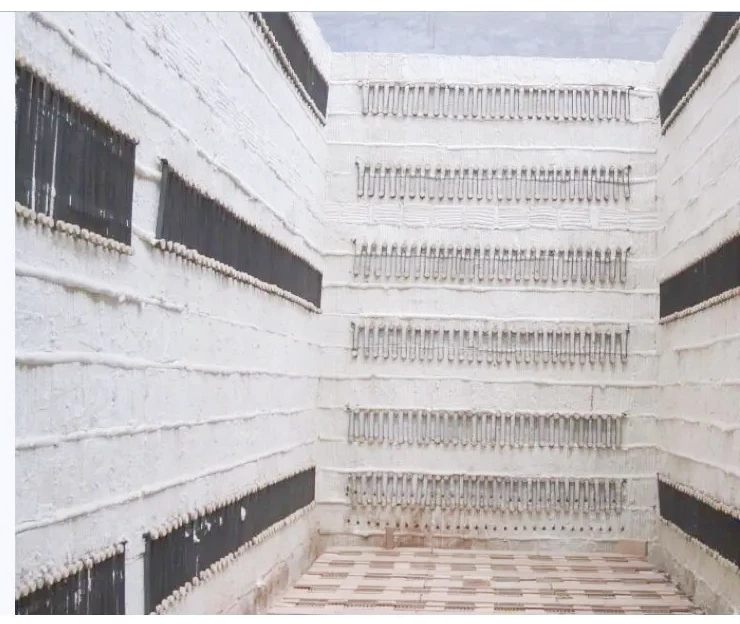

When using a full ceramic fiber lining in an industrial furnace, different grades of fiber must be selected for each layer based on the temperature gradient of the lining. This ensures both cost-effectiveness and cost reduction. The layered structure of ceramic fiber blankets often involves anchoring them through welding pins on steel plates, securing the layers to the furnace wall. Stainless steel mesh is then placed on top to prevent any falling. However, manually installing multiple layers of composite ceramic fiber blankets can be challenging, especially when using more than three types of materials. This is problematic as it not only compromises the quality of the construction but also leads to poor overall integrity of the composite layers.

On the other hand, using lower-temperature ceramic fiber blankets for flat lining, with ceramic fiber modules installed on top, creates a more robust structure. The design incorporates pre-compression elasticity to compensate for the fiber’s natural shrinkage, enhancing the lining’s seal. This results in better overall smoothness and aesthetics. The application of a curing agent on the working surface prevents slag from falling and also prolongs the lifespan of the lining.

The structural advantages of combining ceramic fiber modules with flat-laid blankets are evident in several aspects

- Reduced fuel consumption and increased production yield.

- Lower surface temperature of the furnace.

- Extended lifespan of the furnace.

- Decreased combustion losses.

What is the Best Structure for a Full Ceramic Fiber Furnace Lining?

Currently, common industrial furnaces mostly use full ceramic fiber linings, except for furnaces with high wear and tear, high wind speeds, or complex chemical compositions. The choice of ceramic fiber is based on its high-temperature resistance and light weight. Additionally, a ceramic fiber lining effectively reduces the surface temperature of the furnace, minimizes fuel consumption losses, improves product quality and production yield, and extends the lifespan of the furnace.

As for the structure of the ceramic fiber lining in the kiln, it tends to lean towards a combination of ceramic fiber modules and blankets.

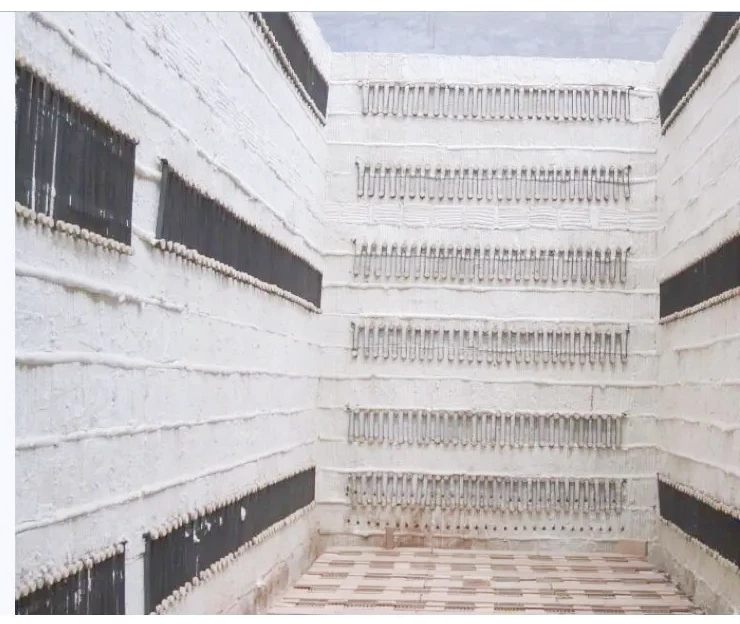

When using a full ceramic fiber lining in an industrial furnace, different grades of fiber must be selected for each layer based on the temperature gradient of the lining. This ensures both cost-effectiveness and cost reduction. The layered structure of ceramic fiber blankets often involves anchoring them through welding pins on steel plates, securing the layers to the furnace wall. Stainless steel mesh is then placed on top to prevent any falling. However, manually installing multiple layers of composite ceramic fiber blankets can be challenging, especially when using more than three types of materials. This is problematic as it not only compromises the quality of the construction but also leads to poor overall integrity of the composite layers.

On the other hand, using lower-temperature ceramic fiber blankets for flat lining, with ceramic fiber modules installed on top, creates a more robust structure. The design incorporates pre-compression elasticity to compensate for the fiber’s natural shrinkage, enhancing the lining’s seal. This results in better overall smoothness and aesthetics. The application of a curing agent on the working surface prevents slag from falling and also prolongs the lifespan of the lining.

The structural advantages of combining ceramic fiber modules with flat-laid blankets are evident in several aspects

- Reduced fuel consumption and increased production yield.

- Lower surface temperature of the furnace.

- Extended lifespan of the furnace.

- Decreased combustion losses.