Why Ceramic Fiber Modules Should Not Be Used at Excessive Temperatures?

Ceramic fiber modules, known as the best partner of industrial kilns, are familiar to all, and it is well understood that material selection based on temperature (operating temperature) is a fundamental principle. But why is this the case?

As a high-temperature refractory insulation product, ceramic fiber modules have a low thermal conductivity and excellent insulation effect. If used within the allowed temperature range, their crystal development will become extremely slow, and its performance will be more stable, allowing it to continue working for 5-10 years.

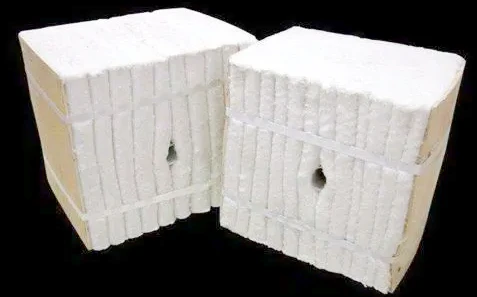

Ceramic fiber modules are inorganic products, which are made of ceramic fiber cotton that is needle-punched and then compressed into blankets. They are classified as Class A non-combustible materials, meaning that when exposed to flames or high temperatures, they do not catch fire, produce smoke, or char. Therefore, ceramic fiber modules do not exhibit any combustion phenomenon, even short-term combustion will not happen.

However, if used in an environment with excessively high temperatures for an extended period, it will accelerate the crystal development inside the ceramic fiber module. The fibrous structure that supports the pores will gradually fracture, reducing the module’s porosity and decreasing its insulation effect. This is manifested in the appearance of the module shrinking in size, and in severe cases, experiencing significant disintegration. The module will gradually detach, causing damage to the furnace body and resulting in incalculable losses.

Furthermore, when ceramic fiber modules are used in kiln environments containing corrosive substances, it is necessary to first determine the operating temperature of the ceramic fiber modules based on the specific fuel used in the kiln. If used in a reducing atmosphere, it is important to select materials and calculate the lining thickness based on the composition of the reducing atmosphere, and apply anti-corrosion coatings to the surface of the ceramic fiber modules.