Why is Ceramic Fiber Blanket Heat Resistant?

Table of Contents

Ceramic is an artificial material known for its heat resistance, wear resistance, corrosion resistance, insulation properties, and resistance to deformation. The emergence of ceramics over ten thousand years ago marked the transition from the Paleolithic era to the Neolithic era.

Ceramic fiber blanket, one of its main components being aluminum oxide, is named so due to its main ingredient being the same as that of ceramics. It inherits the excellent properties of ceramics, such as heat resistance, wear resistance, insulation, and high-temperature resistance. Additionally, due to changes in its internal structure, it overcomes the brittleness associated with ceramics. This is attributed to its production process:

1. Production Process of Ceramic Fiber Blanket

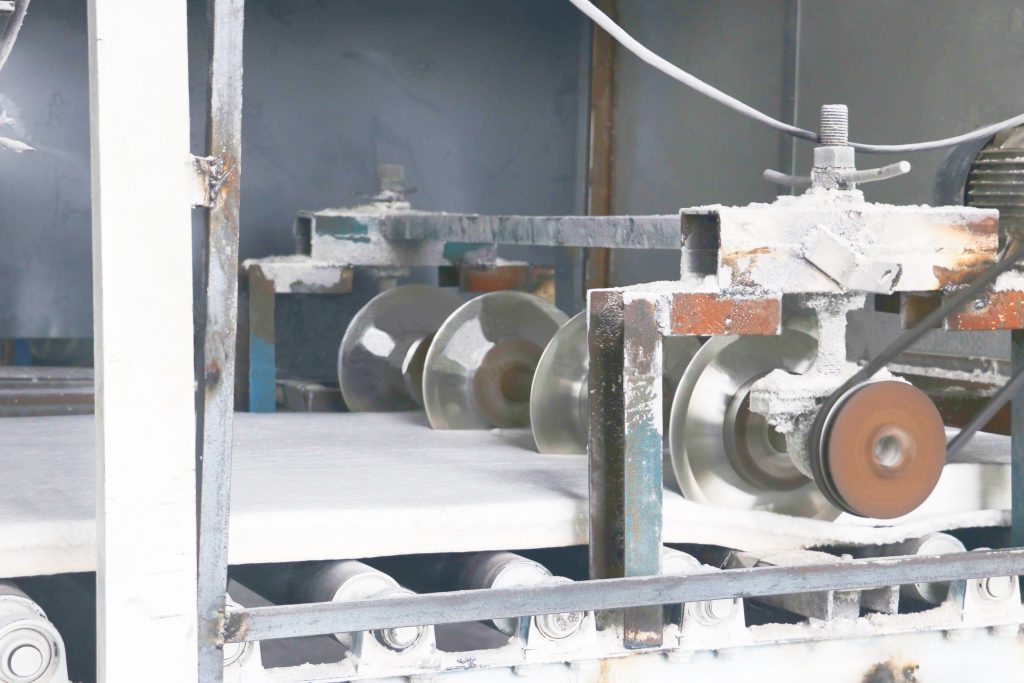

The ceramic fiber blanket is produced using a continuous melting and drawing process in a non-furnace lined water-cooled wall resistance furnace, and then formed by double-sided needling. The fibers of the ceramic fiber blanket are long, thick, and uniform in diameter, with high tensile strength and strong resistance to air flow abrasion. It also exhibits good thermal stability. Through heat treatment in a fully controlled blanket heating furnace, ceramic fiber products undergo phase changes in advance, reducing high-temperature shrinkage during use. High-quality raw materials and specialized purification and mixing production processes are employed to effectively reduce impurity content in the products, enhancing their thermal stability.

2. Different Types of Ceramic Fiber Blankets in Various Production Processes

Ceramic fiber blankets can generally be divided into spun and blown types. The fineness of the ceramic fibers produced by these two processes is different, so there are slight differences in the characteristics and uses of these two types of ceramic fiber blankets.

a) Spun blankets: Compared to the blown process, the spun process produces ceramic fibers that are coarser and longer. Therefore, spun blankets have higher tensile and flexural strength compared to blown blankets. Spun blankets are suitable for insulation environments where high requirements for flexural and tensile strength are needed.

b) Blown blankets: Blown process produces ceramic fibers that are finer compared to the spun process, so although blown blankets have lower tensile and flexural strength compared to spun blankets, the thermal conductivity of blown blankets is lower than that of spun blankets. Blown blankets are suitable for environments where low tear resistance of ceramic fiber blankets is acceptable, but higher requirements for insulation performance are needed.

3. Application of High-Temperature Resistant Ceramic Fiber Blankets

Ceramic fiber blankets exhibit excellent fire resistance and are commonly used for insulation in industrial settings. They are particularly effective as refractory insulation materials in high-temperature kilns. The strong insulating capacity of ceramic fiber blankets allows for significant energy savings, outperforming similar insulating materials like refractory bricks by 1.2 times. Therefore, ceramic fiber blankets are also known as high-temperature resistant ceramic fiber blankets.